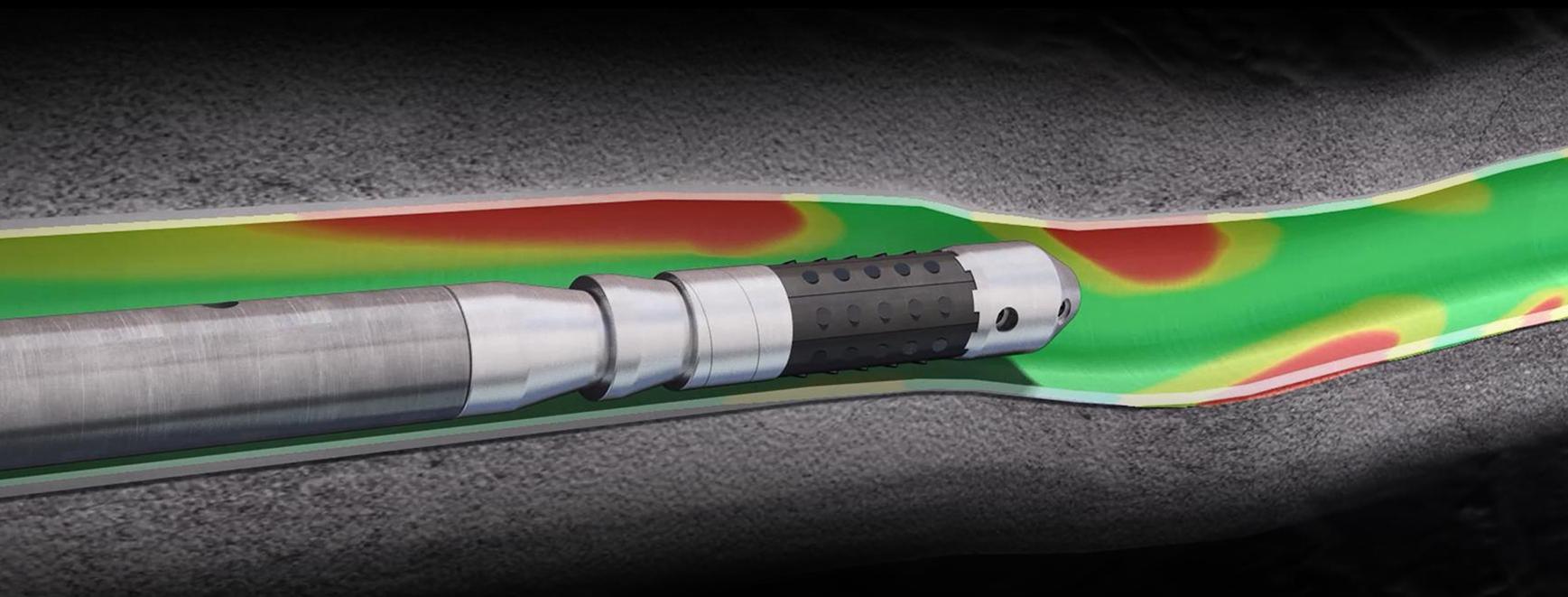

Wizard HEDP Dissolvable Plug delivers a reliable, cost-effective, and customizable solution for modern fracturing and re-frac operations. With an unprecedented expansion range – capable of passing through tight spots and setting in 3.5"–5.5" casings – the Wizard HEDP Dissolvable Plug overcomes challenging downhole restrictions, including collapsed casing sections where conventional plugs fail.

Featuring industry-leading dissolution technology, it eliminates post-job intervention and significantly reduces completion time and risks.

This plug combines the proven performance of the standard Wizard Dissolvable Plug with superior passage capability, making it ideal for extreme well conditions and economically viable for stages that were previously untreatable.

Features

-

Ultra-high expansion, reliably set in 3.5″-5.5″ tubular after passing through tight restrictions

-

Fully dissolvable, eliminates post-frac intervention, reduces downtime & completion costs

-

Metal seal and Hybrid seal available

-

Run with wireline or hydraulic setting tools

Specification

| Casing Size | Casing Weight (lb/ft) | Casing Grade |

| 3.5" | 9.3 | N80 P110 Q125 140V |

| 4.5" | 11.6 - 15.1 | |

| 5" | 15 - 21.4 | |

| 5.5" | 20 - 26.8 |

Case Study

-

BACKGROUND

Casing deformation is a common problem in the southwestern shale region of China. Several factors can cause casing deformity, which can disrupt a smooth plug & perf operation. These factors include changes in formation stress during fracking, poor cementing quality, and mechanical damage during running.

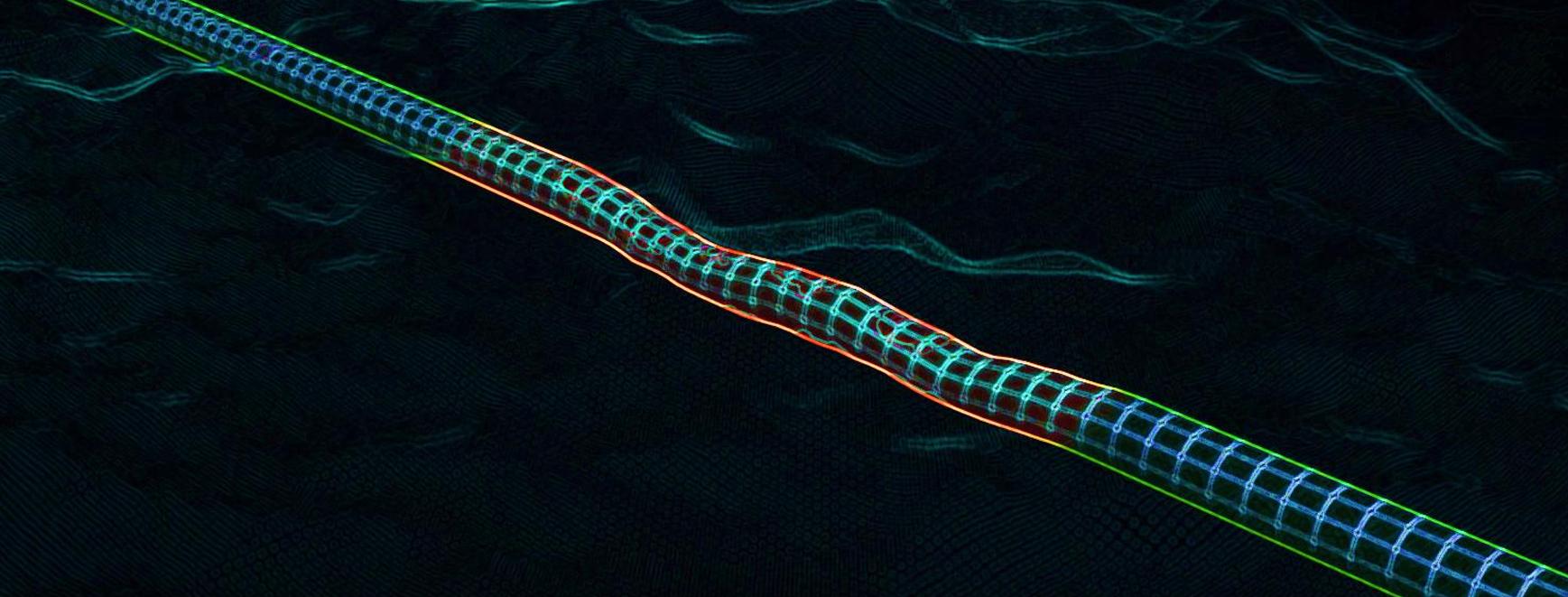

5.5" 26.8# casing is commonly used, while most frac plugs are 4.055" or slightly larger. These frac plugs often encounter restrictions, resulting in stuck bottom hole assemblies (BHAs) and some that are lost in the hole and cannot be retrieved despite multiple attempts.

As a result of these issues, many completions are experiencing non-productive time (NPT) ranging from 3 days up to several weeks. In some cases, wells have even been forced to skip over "problem zones", resulting in a loss of 10% - 23% of total stage counts.

Unfortunately, the frequency and severity of casing deformation have been increasing as hydraulic fracturing activities expand across the region.

-

CHALLENGES

There are currently many high-expansion frac plugs available on the market that are designed to pass through tight spots. However, in some extreme cases, even these tools are unable to effectively address the issue.

For example, in the case described in this study, the restriction is approximately 2.756". To pass through this restriction, the plug and tool string must be smaller than 2.756" and can expand and set inside 4.5" inner diameter casing. This can be a challenging task, especially if the restriction is particularly severe.

Since 2016, Vertechs has been developing and offering high-expansion dissolvable frac plugs to address downhole restrictions. These plugs are designed to save untreatable stages and speed up completions by providing a solution for challenging restrictions.

Vertechs has developed many different types of high-expansion dissolvable frac plugs over the years, but the Wizard HEDP Dissolvable Plug is the only design currently available on the market that can effectively address the specific challenge described in this case study.

-

RESULTS

The Wizard HEDP Dissolvable Plug's outer diameter is only 2.36“

Able to pass through the most severe restriction without any issues

Finally set inside the normal casing by expanding up to 90.5%

7 KPSl of differential pressure was applied to the plug

30+ stages were saved in 6 wells

Saving more than 120 hours in another severely deformed lateral

Technical Video

-

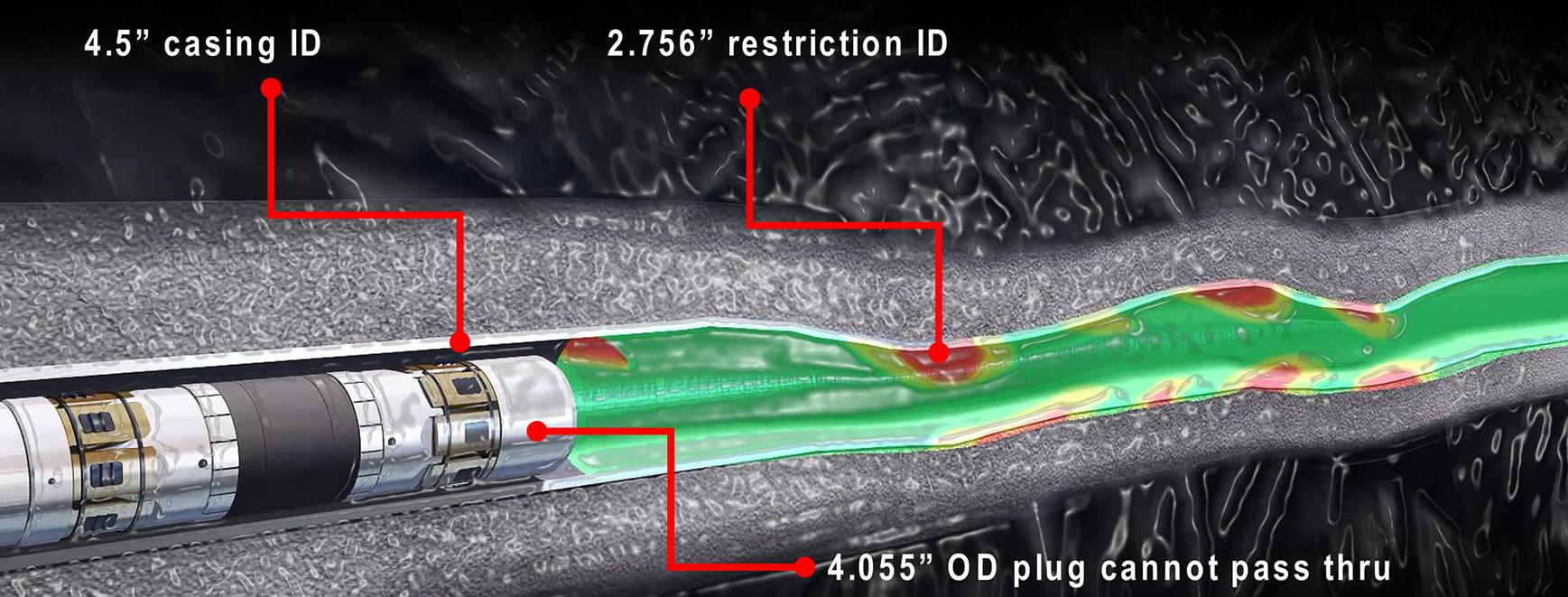

While most frac plugs work well in round casings, dealing with oval casings presents a tougher challenge for isolation. Frac plugs usually expand to fit the casing ID, ensuring even pressure distribution. However, ovality can disrupt this, resulting in unreliable performance and possible leaks. Though we can't fix casing deformation, we're continuously enhancing our dissolvable plugs for complex downhole conditions.