Fluid Monitoring Systems: The Key to Smarter Drilling Solutions - Test

2025-04-09

Are you searching for a system that can help you enhance safety, efficiency, and cost-effectiveness associated with your drilling operations? Here is a solution for you, but before that, answer a question. In this high-tech-driven and fast-paced world of the drilling environment, how do you ensure precise control over the drilling conditions to avoid costly challenges? This is all about managing pressure drilling when advanced solutions such as fluid monitoring systems come into the picture.

Overview of Fluid Monitoring Systems?

Have you ever tried to understand the role of real-time data in transforming drilling operations? It is only the fluid monitoring system that empowers the operations with its ability to make informed decisions, performance optimization, and risk mitigation. If you want to know more about how these systems unlock the doors to smarter drilling solutions, then you need to dive deeper into this guide!

A fluid monitoring system is a refined setup that tracks the properties and performance of the operated fluid. The parameters that are tracked are density, viscosity, pressure, and the rate of flow. In addition to this, these systems are well capable of providing real-time insights into the drilling and fluid conditions. With all this, it is easy to make the adjustments to maintain the effectiveness in the drilling process.

The Role of Fluid Monitoring in Managed Pressure Drilling

Managed Pressure Drilling systems ensure precise control over the wellbore, and with this, they reduce risks such as instability, kicks, and equipment damage. In addition to this, the system operates so many things, let’s get deeper into and understand the exact role of the fluid monitoring system.

Monitor Fluid Properties in Real-Time

Fluid monitoring systems ensure the installation of safe and efficient drilling, and it is possible because of their ability to track density, viscosity and flow rate of the fluid.

Make Data-Driven Decisions

The real-time data provided by the systems shares the ability for operators to make changes in the wellbore to maintain safety and efficiency during managed pressure drilling.

Reduce Non-Productive Time (NPT)

The fluid monitoring systems play a very important role in reducing NPT, which results in less time and money.

Enhance Safety

This fluid monitoring system ensures accurate monitoring of any fluid and make sure build strong control over the pressure of the wellbore. As a result, this reduces the chances of dangerous incidents such as blowouts or kicks, which can destroy the boundary of safety around.

The Key Benefits of Real-Time Fluid Monitoring in Drilling Operations

There are so many advantages of real-time fluid monitoring systems, which directly impact the success of a business via efficient drilling operations. Apart from safety, efficiency, and cost-effectiveness, here you will get deeper into the key benefits of this system, and will understand how it is changing the scenario.

Immediate Response to Pressure Fluctuations

Fluid Monitoring Systems deliver constant smoothness on the pressure of the wellbore, which allows operators to react instantly to the fluctuations. Otherwise, this will lead to dangerous failures.

Continuous Optimization of Drilling Parameters

The system shares the ability to track each property of the fluid and helps operators to make dynamic optimizations to any parameter of drilling. Where such a real-time adjustment will give you an efficient drilling approach, which will reduce equipment wear and in the end, maintain operational stability.

Enhanced Wellbore Integrity

With the fluid monitoring system, you will be able to maintain the integrity of the wellbore and also maintain long-term success for the project. With all these advantages, the system never compromises the overall success of the project.

Unlock the Potential of the Drilling Approach

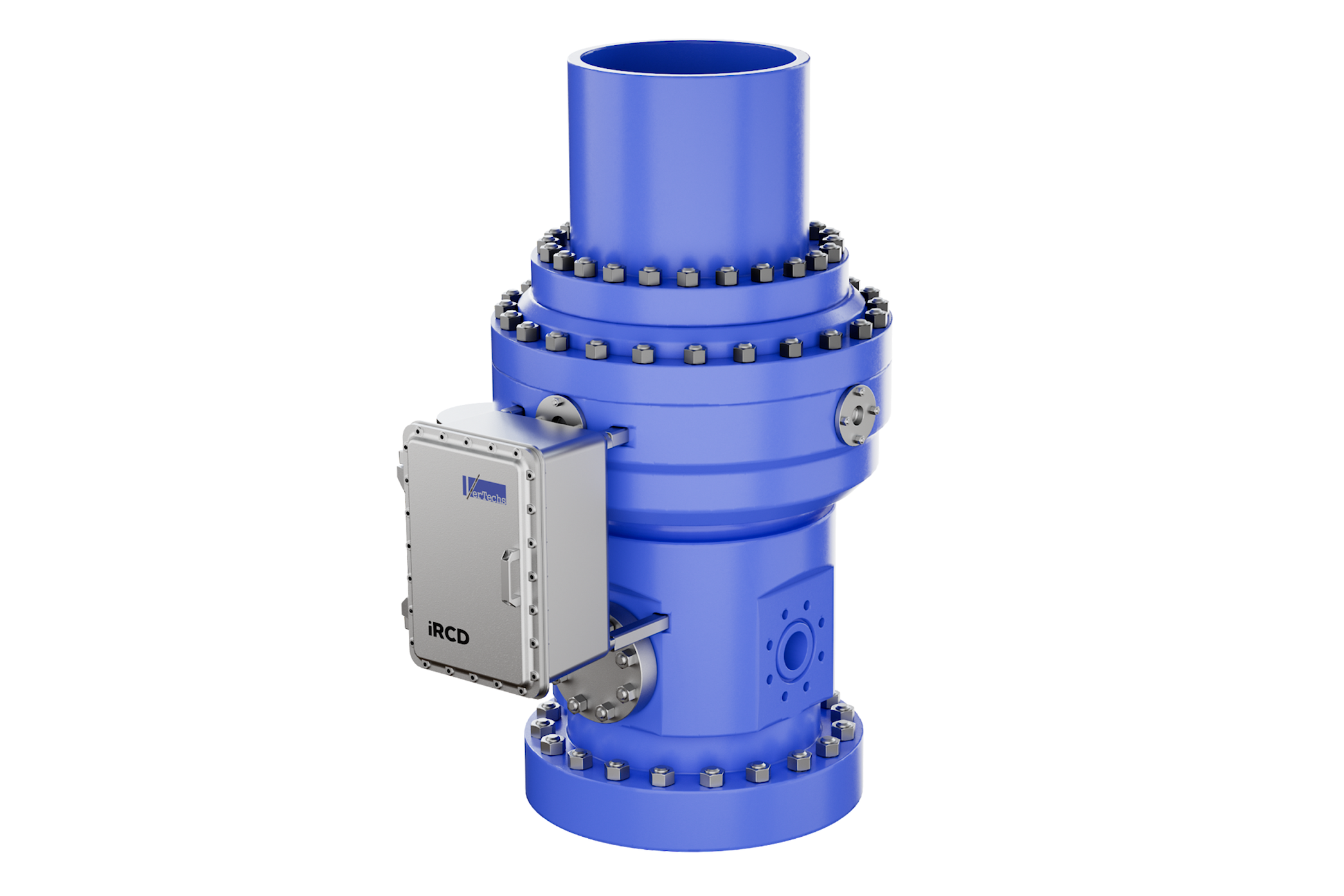

Let’s conclude the guide, hoping that now you understand the importance of reliability and precision to maintain an efficient managed pressure drilling process. If you like the concept behind it and now want to install the same, then Vertechs is recommended for you. This is one of the platforms where you will be able to easily integrate the fluid monitoring system into your managed pressure drilling system. This will give you a straight path to optimized performance by reducing downtime.

Are you ready to transform your drilling operation with advanced and cutting-edge technology? To learn more about how Vertechs can support your energy project, please contact us via email at engineering@vertechs.com.

Read Our One More Blog(1): How Brand Experience Design Agencies Craft Customer Journeys

Read Our One More Blog(2): How Inclusive Design Creates Better Digital Experiences for Everyone?