From Arrival to Operation: How Fast Can MPD Be Deployed?

2025-05-21

Do you believe that time is much more important for the oil and gas drilling industries when it comes to installing a Managed Pressure Drilling (MPD) System? Being a part of a similar industry, do you want to know how quickly you can expect a final setup to initiate the full stack of operations? Or are you in doubt whether a fast deployment is possible or not, or whether it can make a difference in wellbore strengthening, fluid monitoring, and complete efficiency of the production? In this guide, you will get to know everything you need to know for the quick and precise installation.

Let’s dive deeper into things that you will discover here in this guide, so it is about the standard timeline to deploy the MPD system, affecting factors, and an explanation of how to enhance the performance with less cost and downtime. Let’s take a step to dive into the guide and know how fast you can rig up your Managed Pressure Drilling (MPD) system?

What is MPD Drilling?

As the name Managed Pressure Drilling (MPD) is an advanced technique for drilling, with this pressure during the process can be easily and precisely controlled within the wellbore. Managing pressure through the MPD systems will allow an operator to address all the issues, such as lost circulation, wellbore instability, and good control over poor well condition. Configuring such issues will pave the way to the timely completion of the drilling projects.

How Fast Can MPD Be Deployed?

The quick deployment of the MPD system is very important to maintain smoothness in the operations. However, the time for final deployment may vary depending on certain factors; on the basis of those parameters, the deployment time may range from a few hours to days.

Factors Influencing MPD Deployment Time

● Rig complexity: The larger rigs and a complex environment for the rigs may require additional time.

● Operational environment: The Offshore section and deeper drilling requirements need more time for the final deployment because of the requirement for well-specialized equipment.

● Equipment availability: If MPD systems are not pre-configured, then deployment may require a few extra hours.

● Crew expertise: The experts with a specialization in MPD systems can expedite the installation and troubleshooting.

Timeline Breakdown

Environment | Estimated Time For Deployment | Key Factors Affecting Time |

Offshore Deepwater | 24-48 hours | Rig complexity, safety checks, and system configuration |

Onshore Conventional | 12-24 hours | Well depth, equipment availability |

High-Pressure/High-Temperature (HPHT) | 36-72 hours | Specialized equipment, environmental factors |

Extended Reach Drilling | 24-36 hours | Wellbore stability, fluid monitoring setup |

Key Benefits of MPD Deployment

Enhanced Wellbore Strengthening

One of the prime perks of MPD drilling is its ability to stabilize the environment inside the wellbore. With the MPD systems, instability can be well maintained by maintaining consistent pressure. This strengthens the wellbore, and operators will make the drilling safer. As a result, this will reduce the chances of costly issues.

Real-Time Fluid Monitoring

The Managed Pressure Drilling Systems are well-equipped with fluid monitoring systems with advanced technologies. This allows operators to look into the live status and adjust the properties of the fluid accordingly. It shares a way to continuous monitoring that enhances the overall efficiency of the drilling operation as a whole. Let’s understand what it actually does.

● Maintain fluid with optimal properties

● Preventing common issues such as circulation and fluid loss.

● The system ensures a smooth run throughout the drilling process, which is done by adjusting the pressure and the rate of the flow of the fluid as required.

Reduced Non-Productive Time (NPT)

Here, NPT stands for non-productive time, which is one of the expensive drilling aspects. However, MPD Drilling is something that can reduce the NPT time by preventing and controlling issues throughout the process.

Power Up Your Wells With MPD

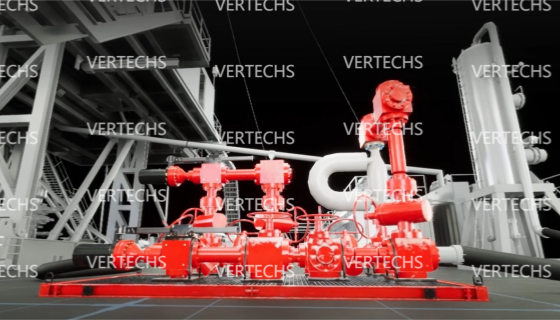

Hope you find the way to “How fast can you rig up your Managed Pressure Drilling (MPD) system?”. As you have read above, the MPD Drilling is completely transforming the way the oil and gas industries approach construction. Where the abilities of MPD systems make it easier, if you are also looking for a solution to wellbore strengthening, integrated with a fluid monitoring system and other advancements, then Vertech is one of the platforms specialized in the same.

Are you ready to invest in optimising the efficiency and stability through the drilling process? Look into the advanced MPD technologies at Vertech, contact the team by filling out a form on the official site, and get a well-tailored solution.

Frequently Asked Questions

1. Can MPD systems be customized as per the specific wellbore conditions?

Yes, MPD systems can be easily tailored to meet the standards and conditions of any complex wellbore. No matter how high the pressure, temperature, and drilling needs are. Thus, performance can be optimized for any project.

2. What are the technologies embedded into MPD systems for real-time fluid monitoring?

MPD systems are designed with advanced fluid monitoring technologies. This includes real-time sensors, automatic pressure control tools; this way system can continuously asses the process and adjust the parameters to reserve high performance.

3. What is the role of MPD systems in preventing lost circulation?

The MPD systems prevent the lost circulation by managing the pressure inside and make sure the liquid is maintained at the optimal fluid rate and pressure.

4. What are the additional benefits of MPD systems, apart from fluid monitoring and wellbore strengthening?

The MPD systems are also helpful to optimize the parameters associated with the drilling process, safety improvements through real-time data, and enhancement in the efficiency by preventing the risk of complications.

Vertechs Group is a leading international energy technology company, offering a comprehensive range of digital application upgrades, AI engineering applications, and disruptive downhole technology products. Headquartered in Chengdu, China, with branches in the United States, Canada, and Hong Kong, Vertechs is committed to providing innovative solutions that drive efficiency and sustainability in the energy industry. Their mission is to deliver cutting-edge technologies and establish a development platform for employees, creating sustainable value for society.

To learn more about how Vertechs can support your energy technology needs, please contact us, via email at engineering@vertechs.com.

Read Our One More Blog(1): Innovative Solutions for Well Integrity: Dissolvable Frac Plugs in Focus

Read Our One More Blog(2): Vertechs' Innovations in HPHT Frac Plug Materials and Coatings