Breaking Down the Benefits of Dissolvable Frac Plugs - Test

2024-05-02

Introduction to Dissolvable Frac Plugs

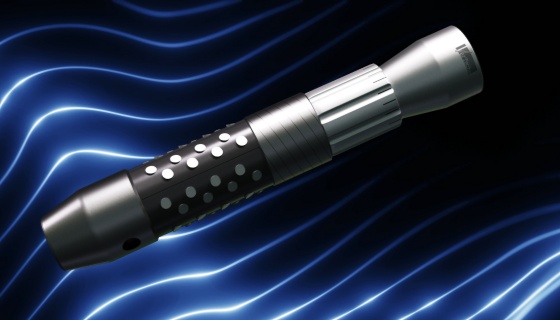

In the realm of oil and gas well completion, dissolvable frac plugs have emerged as innovative solutions, offering significant advantages over traditional plug-and-perf methods. Provided by industry leaders like Vertechs, dissolvable frac plugs are engineered to seamlessly disintegrate in the wellbore environment, eliminating the need for costly plug retrieval operations. Understanding the benefits of dissolvable frac plugs is essential for operators seeking to enhance operational efficiency and reduce environmental impact.

Exploring Dissolvable Frac Plugs

Dissolvable frac plugs are downhole tools designed to temporarily isolate specific zones within the wellbore during hydraulic fracturing operations. Unlike conventional frac plugs, which require milling or retrieval after fracturing is complete, dissolvable frac plugs are manufactured from materials that dissolve or degrade over time in the downhole environment. This innovative design eliminates the need for plug retrieval, reducing costs, and simplifying wellbore cleanup processes.

Key Benefits of Dissolvable Frac Plugs

Enhanced Operational Efficiency

One of the primary benefits of dissolvable frac plugs is enhanced operational efficiency. Traditional plug-and-perf methods require multiple trips in and out of the wellbore to deploy and retrieve frac plugs, leading to increased rig time and operational costs. In contrast, dissolvable frac plugs dissolve naturally over time, eliminating the need for plug retrieval operations and streamlining the well completion process. This increased efficiency translates into cost savings and improved project economics for operators.

Reduced Environmental Impact

Dissolvable frac plugs offer significant environmental benefits compared to traditional plug-and-perf methods. By eliminating the need for plug retrieval, dissolvable frac plugs reduce the volume of waste generated during well completion operations. Additionally, the dissolution of frac plugs in the downhole environment minimizes the risk of formation damage and fluid migration, enhancing environmental sustainability and ensuring compliance with regulatory standards.

Factors Influencing Dissolvable Frac Plug Selection

Material Composition

The material composition of dissolvable frac plugs plays a crucial role in determining their dissolution rate and performance characteristics. Manufacturers like Vertechs offer a range of dissolvable frac plug solutions designed to meet specific wellbore conditions and operational requirements. Operators must consider factors such as wellbore temperature, fluid chemistry, and dissolution kinetics when selecting dissolvable frac plugs for a particular application.

Downhole Conditions

Downhole conditions, including temperature, pressure, and fluid composition, influence the performance of dissolvable frac plugs. Operators must ensure that selected frac plugs are compatible with anticipated downhole conditions to prevent premature dissolution or failure. Collaboration with experienced service providers and thorough evaluation of well data are essential for selecting dissolvable frac plugs that can withstand the rigors of the downhole environment.

Conclusion

Experience the future of energy technology with Vertechs Group. Connect with our team at Unit 2, Building 6, No.1166 Tianlong Avenue, Chengdu, or delve into our solutions online at https://www.vertechs.com/. For personalized service, call us at +86 28 8325 7686 or email admin@vertechs.com and marketing@vertechs.com. Let Vertechs Group be your partner in driving innovation and success in the energy industry.