Mastering Modern Drilling: How Advanced Well Control Systems and Services Enhance Safety and Efficiency

2025-11-14

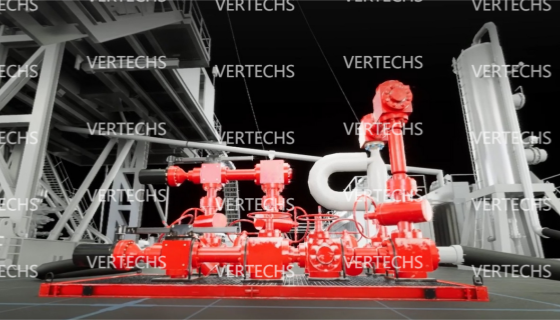

In the complex and high-stakes world of oil and gas extraction, maintaining precise control over drilling operations is crucial for safety, efficiency, and environmental protection. Well control, a critical aspect of this process, ensures that oil and gas flows are carefully managed to prevent blowouts and other hazardous incidents. Companies specializing in well control, like Vertechs, provide a comprehensive suite of services and equipment that allow operators to monitor, regulate, and stabilize wellbore pressures in real time. By leveraging cutting-edge technology, these well control companies not only mitigate risk but also enhance overall drilling performance.

Well control drilling relies on an intricate interplay between specialized equipment and expert management. At the heart of this capability are advanced well control systems, which integrate intelligent sensors, automated monitoring, and adaptive control mechanisms. Such systems are designed to respond to fluctuations in wellbore conditions, ensuring that pressure remains within safe limits. For instance, Vertechs’ Real-Time Wellbore Strengthening Solution (RWSS) exemplifies how modern technology can continuously assess formation integrity, adjusting parameters dynamically to prevent fluid loss and maintain operational stability. By using this type of system, drilling teams can proactively address potential hazards before they escalate into costly or dangerous situations.

A well control company like Vertechs offers an array of equipment tailored to specific operational needs. Intelligent rotating control devices, precision chokes, and manifold systems enable operators to execute managed pressure drilling (MPD) with unprecedented accuracy. These tools are complemented by sophisticated monitoring technologies that track drilling fluid behavior, wellbore pressures, and other critical parameters. For example, the REALology Intelligent Drilling Fluids Monitoring System automatically collects data in real time, reducing the likelihood of non-productive time and enabling more efficient decision-making. Such integration of equipment and software underscores the importance of a well-rounded well control strategy in modern drilling operations.

Beyond equipment, well control services encompass expert consultation, training, and operational support. The role of a well control company extends to advising on best practices, implementing safety protocols, and ensuring compliance with regulatory standards. Companies like Vertechs also emphasize digital solutions and artificial intelligence to enhance predictive capabilities, allowing drilling teams to anticipate challenges and optimize workflows. By combining human expertise with technological sophistication, these services create a more resilient and responsive drilling environment, capable of adapting to complex geological and operational conditions.

The synergy between well control equipment and services demonstrates how a holistic approach benefits both safety and productivity. For instance, the integration of intelligent pressure control systems with real-time monitoring platforms allows operators to make informed adjustments instantly. This reduces the risks associated with sudden pressure changes or formation instability while also improving overall drilling efficiency. Well control companies thus play a dual role: protecting personnel and assets while facilitating smoother, faster drilling operations. In this way, the value of investing in both high-quality equipment and comprehensive well control services becomes evident, as it enhances reliability and lowers operational costs over time.

In an era where energy demands are ever-increasing, the need for precision in drilling operations has never been more pronounced. Modern well control systems, provided by experienced well control companies, combine advanced mechanical devices with digital intelligence to manage complex subsurface environments. From managed pressure drilling to intelligent fluid monitoring, these technologies allow operators to maintain control under challenging conditions, reducing environmental risks and improving project outcomes. Companies such as Vertechs continue to push the boundaries of what is possible in well control drilling, demonstrating that innovation, expertise, and strategic application of technology are essential for safe and efficient oil and gas extraction.

In conclusion, well control is far more than a technical requirement; it is a comprehensive approach that encompasses specialized equipment, real-time monitoring, expert guidance, and adaptive systems. Well control companies, exemplified by Vertechs, provide the tools and services necessary to navigate the complexities of modern drilling operations. By integrating intelligent systems, precise equipment, and expert support, these companies help ensure operational safety, optimize performance, and reduce risk, making them indispensable partners in the energy industry. Please contact us, at engineering@vertechs.com to learn more about how we can support your next project.

Read Our One More Blog(1): The Future of Plug and Perf: How Dissolvable Tools Are Changing Well Completions!

Read Our One More Blog(2): Fluid Rheology and Intelligent Well Technologies: Transforming Energy Solutions in Saudi Arabia