How Intelligent Rotating Control Devices are Changing Well Pressure Management

2025-09-25

The role of technologies is nowadays evident in the sectors and industries. Technologies have kept the work safer, efficient, and sustainable. The oil and gas industry is no exception. In this industry, one of the many technologies that is bringing a kind of revolution is the rotating control device. Earlier, it was considered a supporting tool for managed pressure drilling, but now, it has emerged as an important asset in controlling wellbore pressure. This device helps in minimizing risks and improving drilling performance. As there are several visible and pressing challenges in the industry, such as drilling deeper, harsh environments, and the challenge to meet stricter safety and environmental standards, integrating the RCDs can transform the well pressure management into a predictive, automated, and streamlined process.

In this blog, we are going to explore the contributions of rotating control devices in changing the well pressure management. So, make sure you read it till the very end so that you can have a clear understanding of it.

The Evolution of Rotating Control Devices

The conventional RCDs have been developed to play a simple but important role: to divert the drilling fluid returns out of the rig floor, but remain a closed-loop system. This enabled the operators to control the annular pressure and minimize the probability of kicks, blowouts, or fluid losses.

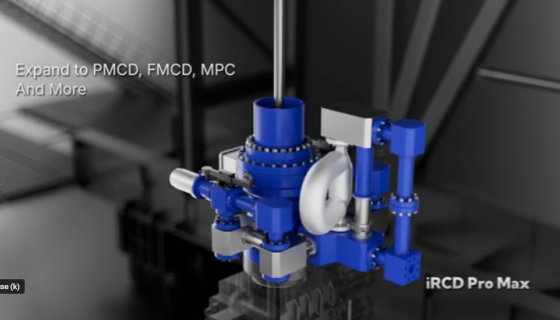

Nevertheless, with more complicated drilling being done, more intelligent and adaptive solutions were required. In this came the smart rotating control gadgets. Intelligent RCDs, unlike their traditional counterparts, possess the addition of sophisticated sensors, digital interfaces, and real-time monitoring capabilities. The improvements permit accurate pressure regulation, enhanced connection with the MPD systems, and enhanced efficiency of the work.

The Importance of Intelligent RCDs in the Contemporary Drilling

1. Real-Time Well Pressure Monitoring

Intelligent RCDs have one of the most notable features that allow them to give real-time data on the conditions of wellbores. With proper pressure measurements and sending them to the controlling system, the drilling teams are able to make quicker and better decisions. This not only saves time but also aids in the avoidance of risky pressure variation, which might cause endangerment of the operation.

2. Greater Safety and Risk Control

The oil and gas industry has always given a place of importance to safety. Intelligent RCDs enhance better control of the well by a constant annular seal to ensure minimal chances of uncontrolled influx of hydrocarbons. They may also be integrated into automated systems to issue alarms or corrective actions in the event of an anomaly in the pressure being detected, as an extra protection against blowouts.

3. Greater Smoothing of Systems with MPD

Managed pressure drilling is dependent on the accurate regulation of bottom-hole pressure. Smart rotating control devices are compatible with the MPD systems, and the required pressure window is always achieved. The integration allows drilling on the narrow-margin reservoirs that would otherwise not be deemed as economical or safe.

4. Cost-Saving and Operational Efficiency

Intelligent RCDs help minimize the possibility of non-productive time (NPT) by maximizing the control of pressure in the case of well-controlled accidents or lost circulation. This will translate to a lot of cost savings to the operators, since downtime is among the most costly factors of drilling works. Besides, better efficiency will result in expedited drilling and favourable use of resources.

5. Predictive Insights and Digitalization

As the oil and gas industry moves towards digital transformation, intelligent RCDs are also playing a role in the transition to predictive analytics. The information gathered by such devices can be combined with machine learning algorithms to predict the situations associated with pressure before they arise. This predictive power will improve decision-making and decrease the use of reactive actions.

Applications Over Drilling Conditions

The intelligent RCDs are becoming useful in a very broad variety of drilling conditions:

Deepwater Drilling: Intelligent RCDs have the level of accuracy required to drill safely in harsh environments in offshore operations where pressure margins are smaller and stakes are even greater.

Unconventional Reservoirs: In shale and tight oil and gas that require pressure attention, intelligent RCDs allow the operator to drill more confidently and efficiently.

High-Pressure, High-Temperature (HPHT) Wells: These are the environments that are very demanding, and the equipment must endure these conditions. The intelligent RCDs are designed using high-quality materials and effective sealing technology to overcome the HPHT challenges.

The Future of Well Pressure Management using Intelligent RCDs

In the future, the role of intelligent RCDs in the digital oilfield ecosystem should continue to increase. With the rise of artificial intelligence (AI) and the Internet of Things (IoT), RCDs will be smarter and more independent, which will be able to not only monitor but also predict and control well pressure with minimal or no human intervention.

Moreover, sustainability as an area will also shape the development of RCDs. Intelligent RCDs will help the industry to be more socially responsible in its drilling operations by minimizing the chances of spills, blowouts, and other activities that may cause environmental degradation.

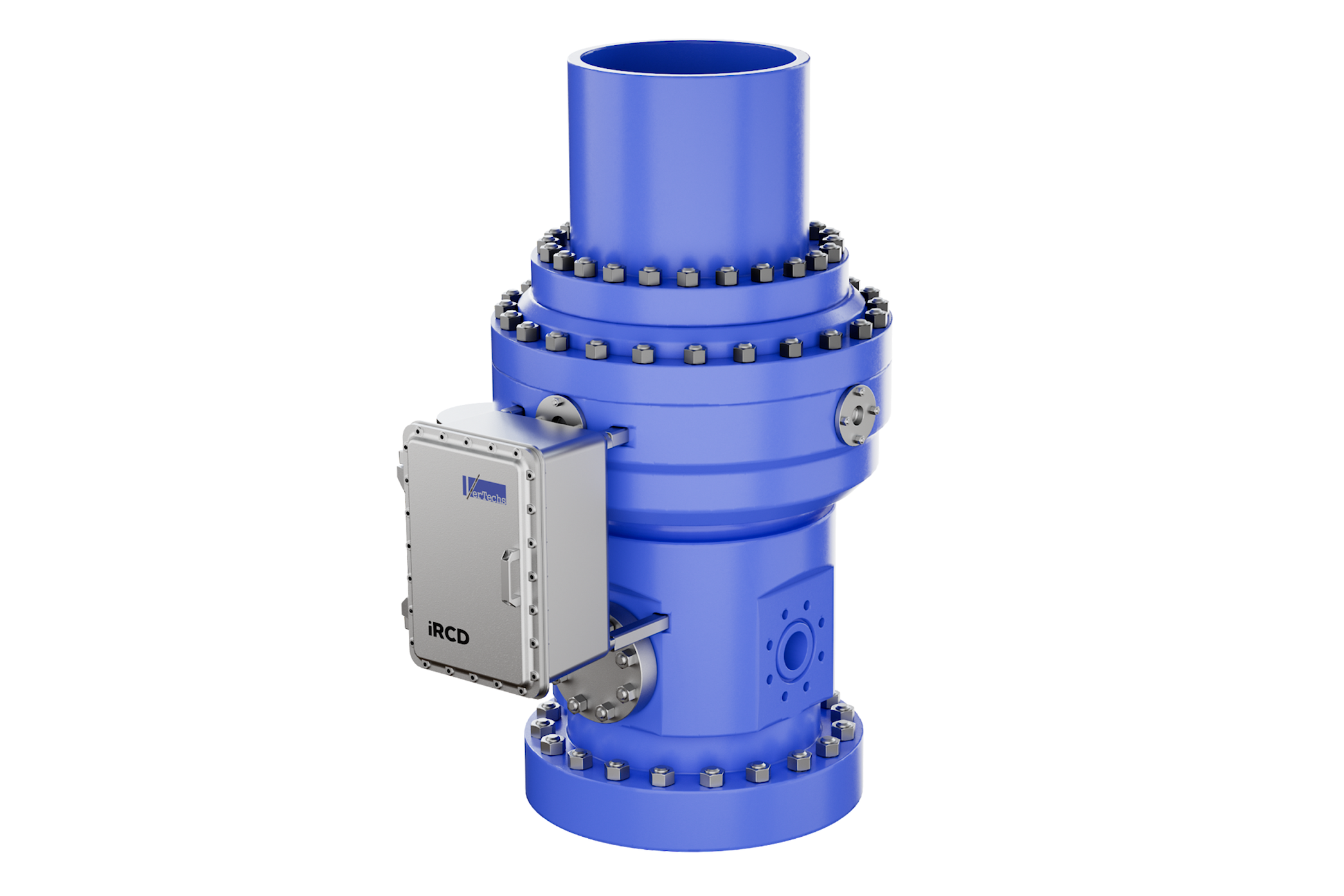

Vertechs Group - Rebranding Well Pressure Management

At Vertechs Group, we believe in providing innovative solutions in drilling that would enable the oil and gas industry to be more efficient, safer, and sustainable. We have several years of experience in utilizing highly innovative well control methods, such as the rotating control device, to guarantee effective and accurate control of pressure in various drilling conditions. Our team constantly challenges engineering and digital innovation limits to offer our clients equipment that helps minimize risks, enhance performance, and minimize costs. The concept of creating products in Vertechs Group does not stop at creating a product, but a solution that propels the future of energy exploration.

Frequently Asked Questions

1. What is the purpose of a rotating control device?

Drilling is achieved by making a closed-loop system through the use of a rotating control device to provide an opportunity to manage well pressure and divert fluids.

2. What are the benefits of intelligent rotating control devices to safety?

They improve safety through real-time check of the well conditions, stable annular seals, and minimize the possible occurrence of blowouts.

3. Is it possible to apply rotating control devices in drilling deepwater?

Yes, they are very common in deepwater works where control of pressure is of great importance.

4. In which industries can rotating control be helpful?

The oil and gas industry, most of which is in the field of managed pressure drilling and high-pressure/high-temperature wells.

5. What is the role of Vertechs Group in drilling?

We also offer superior well control equipment and rotating control equipment, which are intelligent to assist the operators in enhancing efficiency, safety and sustainability.

Read Our One More Blog(1): Managed Pressure Drilling Made Smarter: Key Innovations You Need to Know

Read Our One More Blog(2): Top Challenges in Well Control: Why Fluid Rheology Matters More Than Ever