Optimizing Drilling Operations with Real-Time Fluid Monitoring from Vertechs

2025-05-28

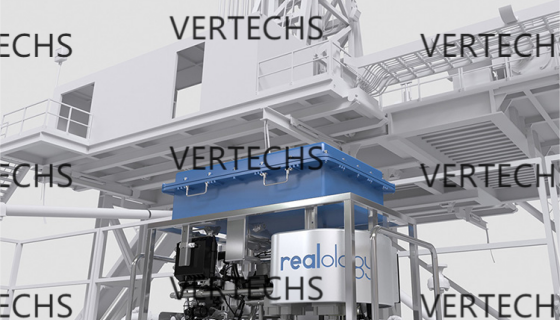

In the ever-evolving landscape of oil and gas drilling, the demand for precision, efficiency, and safety has never been more paramount. Central to achieving these objectives is the integration of advanced technologies that offer real-time insights into drilling operations. Vertechs' REALology Intelligent Drilling Fluids Monitoring System stands at the forefront of this technological revolution, redefining how drilling fluids are monitored and managed.

Traditional methods of monitoring drilling fluids often relied on manual sampling and laboratory analyses, processes that were not only time-consuming but also prone to delays in data acquisition. Such delays could lead to suboptimal adjustments, increased non-productive time (NPT), and potential safety hazards. Recognizing these challenges, Vertechs developed the REALology system to provide continuous, real-time monitoring of drilling fluid properties. This system measures key parameters such as density, temperature, rheology, chlorides, and pH levels, offering drilling engineers immediate access to critical data.

The modular and customizable design of the REALology system allows for flexibility to meet diverse application needs. Its compact and lightweight structure enables easy deployment, even in space-constrained rig environments. With IP65 ingress protection and Exdb II BT4 Gb hazardous area certification, the system is well-suited for offshore applications, where environmental conditions can be particularly harsh.

One of the standout features of the REALology system is its autonomous operation. By providing continuous real-time data, drilling engineers can make informed decisions promptly, enhancing drilling performance and reducing NPT. The system's ability to offer real-time visibility into drilling fluid parameters empowers operators to optimize fluid properties on the fly, leading to improved operational efficiency and profitability.

Beyond its technical capabilities, the REALology system plays a pivotal role in enhancing drilling safety. By continuously monitoring drilling fluid properties, the system can detect anomalies that may indicate potential issues such as wellbore instability or influxes. Early detection of such anomalies allows for proactive measures to prevent well control incidents, thereby safeguarding personnel and the environment.

Furthermore, the integration of the REALology system with Managed Pressure Drilling (MPD) techniques exemplifies the synergy between advanced fluid monitoring and dynamic pressure management. This combination enables precise control of wellbore pressure, reducing the risk of kicks and blowouts, and ensuring optimal drilling conditions.

In addition to safety and efficiency, environmental stewardship is a core focus of Vertechs' drilling fluid solutions. By providing accurate, real-time data on drilling fluid properties, the REALology system minimizes the environmental impact of drilling operations. Precise control over fluid properties reduces waste generation and ensures compliance with environmental regulations.

Vertechs' commitment to innovation extends beyond the REALology system. The company offers a comprehensive suite of drilling fluid products and services, including advanced drilling fluid additives and customized drilling fluid solutions tailored to specific well conditions. By leveraging cutting-edge technologies and a deep understanding of drilling dynamics, Vertechs continues to set new industry standards in drilling fluid management. If you're looking for a trusted partner to optimize your operations, contact us today. Our experts are ready to provide customized solutions tailored to your needs. Reach out via email at engineering@vertechs.com or connect with us on LinkedIn to start a conversation.

Read Our One More Blog(1): From Arrival to Operation: How Fast Can MPD Be Deployed?

Read Our One More Blog(2): Innovative Solutions for Well Integrity: Dissolvable Frac Plugs in Focus