A Complete Guide to Selecting the Right Rotating Control Device for Your Project

2025-10-31

Are you running modern drilling operations, but lagging because of a lack of efficiency, safety, and precision? If you don’t feel confident that the pressure control system will handle all the complex wellbore conditions, then you must look into the efficiency and precision of RCD, which stands for rotating Control Device. Wellbore is indeed all integrated with valuable components that play an important role in maintaining operational control and full reliability, even under high-pressure conditions. Within the MPD (Managed Pressure Drilling) environment, RCD is one of the prime component that contributes to the operational efficiency of the system. Thus, you need to make the right and precise selection for the same. However, if you don’t know how to catch up with the suitable Rotating Control Device, then here is your guide that will convey to you all the supreme factors, and much more information to make an informed choice, or to elevate the drilling operations, and reach the project success.

Understand What Is a Rotating Control Device

RCD, a rotating control device, is integrated into the managed pressure drilling system to manage pressure and the fluid to maintain throughout the drilling operation. Let's understand what the actual working of RCDs is. They are used to build a seal across the drilling string that maintains efficient rotational and vertical movement. It is one of the supreme functionalities of MPD, and UBD (Underbalanced Drilling) system; these are the two systems where precision is necessary, especially when it is a tough game to control pressure to maintain safety, and stability of the entire environment.

How a Rotating Control Device Works

When it comes to operating RCDs, it is all about maintaining the seal with the rotating drill that diverts the annual return and keeps the surface safe. With all this, the fluids, cuttings, gases, or fluids can be easily managed in a well-closed looping system. Also, you will be able to monitor the entire processing and adjust the pressure across.

Types of Rotating Control Devices Available

As per the current dynamic environment, different drilling environments demand different types of RCDs. As nothing is similar in specifications, here is the clear classification of the RCDs that you must be aware of:

Passive RCDs: These are simple mechanical, fundamental pressure control devices.

Active RCDs: We are now offering improved bearing assembly and sealing technology for a greater pressure range.

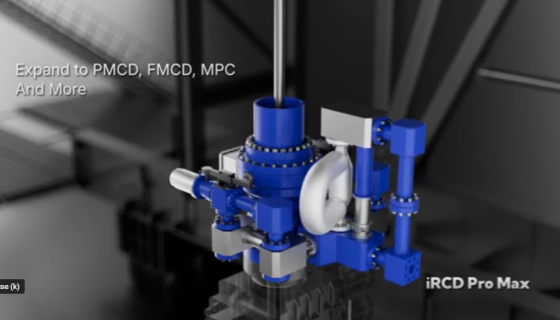

Intelligence/Electronic RCDs: All electric systems with real-time monitoring on intelligent control software for more efficient and accurate MPD

Surface vs Subsea RCD: Surface RCDs are typically utilized on conventional rigs, whereas subsea RCDs or used for deepwater and offshore applications.

Why the Right RCD Matters

Why modern wellbore industries prefer to be strategic while selecting the Rotating Control Device due to several reasons, as mentioned below:

Safety: Provides a safe mechanism for holding wellbore pressures and drilling fluids.

Efficiency: Decreases non-productive time due to reliable wellbore condition management during productive intervals of time.

Cost: Reduced maintenance and reduced downtime with reliable operation.

Environmental: A 100% leak-free operation will reduce the impact on the environment while still supporting sustainability through a reduced environmental footprint.

Key Factors to Consider When Selecting an RCD

If you want to proceed further to make the ideal selection of the rotating Control Device then, first you must know what you have to consider while choosing the same. The below factors are helpful for you as they can give you operations, technical, as well as commercial stability throughout the entire process.

Pressure Rating and Sealing Integrity: Verify if the pressure rating of the Riser Casing Drilling (RCD) is suitable for the overall project specifications, and that it is capable of providing consistently reliable sealing at the various RCD pressure ratings under changing conditions in the prepared wellbore.

Bearing Assembly and Maintenance: Investigate bearings type, lubrication requirements and overall access to servicing to determine if product performance and maintainability is acceptable.

Compatibility/installation: Review compatibility with existing rigs, riser systems, and BOP stacks. The ability of a RCD to be adaptable/suitable will speed up installation timing and assist in decreasing operational down time.

Automation and Intelligent Control: Explore RCDs that include electric actuation as well as providing adaptive algorithms for control output with remote monitoring/running capabilities.

ESG/environmental considerations: Select devices based on their potential sustainability benefits, environmental impact, and potential to mitigate CO2 emissions.

Final Thoughts

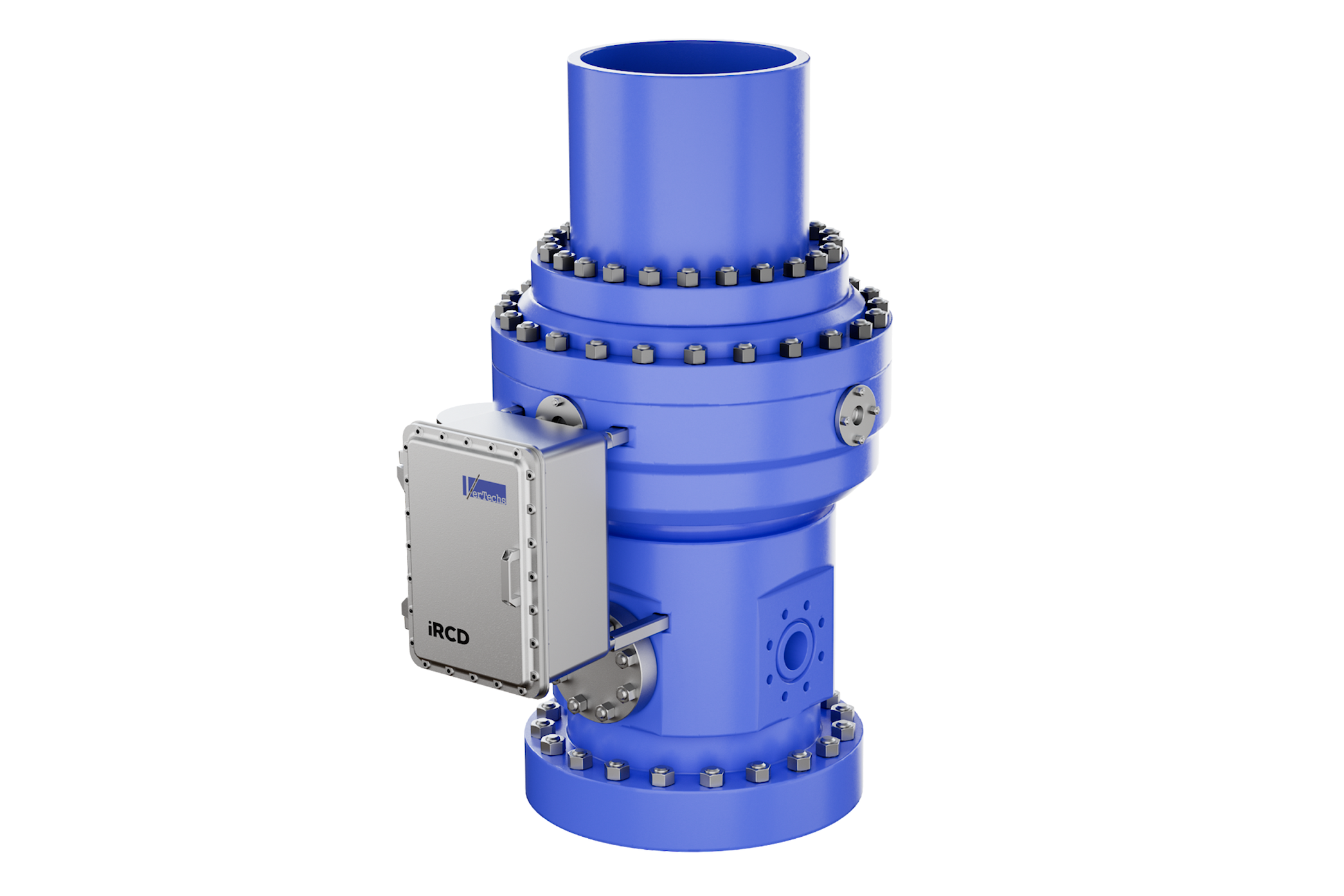

Choosing the ideal rotating control device is not just picking the RCD; it involves strategic thinking, as it is something that leads to improving safety, efficiency, and the overall results delivered by the drilling environment. For all this, you have to be particular with the technicalities, compatibility, environmental factors, and the operational demands you want to lock into the environment. However, it is not what is actually enough; you may need professional support for the same, so Vertech is the leading platform, where the experts can guide and provide you with an RCD. Rotating Control Device that reshapes the control, reliability, adaptability, and precision throughout the wellbore.

Contact the Vertech team via Email: engineering@vertechs.com and explore the innovative versions of the RCDs, Rotating Control Devices, and take a step further to elevate the safety and performance of the entire drilling system. The team is active in providing customized support at every stage of the entire drilling process.

Frequently Asked Questions

Why rotating control device is all unique and valuable?

The RCD, Rotating Control Device, is a crucial component that maintains strong sealing, precise pressure control, safety, and efficiency throughout the complex drilling environments.

How frequently must you inspect the RCDs?

When it comes to inspection, the overall functionality must be checked before, during, and after every drilling phase. This is what is important to ensure the optimal performance and reliability.

Does technology anywhere contribute to enhancing the overall performance of the RCD?

The innovative Rotating Control Devices come with real-time monitoring, that automate the pressure level, and allows precision and safety in the drilling environment by revising the data-driven insights.

Why Vertechs is the right choice for RCD solutions?

Our solutions at Vertech are the preferred choice for modern drilling environments that share the exceptional reliability, operational sustainability, and priceness.

Read Our One More Blog(1): Frac Plugs and the Future of Energy Services in Saudi Arabia

Read Our One More Blog(2): Understanding Loss Circulation in Drilling: Causes, Types, and Solutions