Top Benefits of Managed Pressure Drilling for Deepwater Operations

2025-10-10

Are you taking a step back to invest in the MPD (Managed Pressure Drilling) to manage deepwater drilling systems? It is entirely understandable that deepwater drilling is a critical component in the entire framework of energy production. It is a tough challenge to keep the production line efficient, especially in the oil and gas industry. Not only this, this is there are so many challenges in the deepwater drilling operations, where Managed Pressure Drilling is something that is preferred by most of the modern businesses, and industries, where the base is drilling, as it has all the solutions to resolve any challange that can arise even in the deepwater well, and infact, before, after, and inbetween the operation. However, this may not be enough to attract investment in Managed Pressure Drilling; thus, this guide is dedicated solely to MPD. Here in this guide, you will learn all the supreme benefits that come with MPD, with respect to the Deepwater operational line.

Understand the Role Of MPD in Deepwater Wells and Operations

MPD (Managed Pressure Drilling) is recognized as one of the most advanced and technically sophisticated approaches that can address challenges in drilling, regardless of the current conditions inside and outside the well. If you are in a related industry, you are aware that the deepwater pressure and temperature conditions are too high; therefore, it is particularly challenging to maintain efficiency through Managed Pressure Drilling. Not only this, the MPD is also preferred by senior business or industry owners to avoid blowouts, kicks, and other issues that require instant and precise control.

Why Managed Pressure Drilling Is An Essential Pillar For Deepwater Drilling Operations

In this section, you will understand the real value of MPD (Managed Pressure Drilling). With this, you will analyze how MPD can positively impact your business or industry. Let’s start the guide without wasting even a second

Cost Saving Technique

It is true that when it comes to making such an investment, it is crucial to create a budget first. As deepwater operations present numerous challenges, it is therefore necessary to define a budget. However, installing the Managed Pressure Drilling System under professional support and guidance can help reduce costs.

Highly Durable Solution

The Managed Pressure Drilling Solution comes with a high initial investment; however, it addresses several challenges deep inside the wellbore with a single solution. In addition, there is no need for frequent replacements, as this is something that offers lasting durability, even in complex structures and heavy drilling wellbores.

Efficient Drillinbility

One of the primary reasons for incorporating MPD in modern drilling wellbore systems is the need for drilling within the wellbore, or a portion of it. The precise the drilling, the efficient the entire production.

Precise Influx Management

To maintain a standardized control deepwater inside the well is quite typical; the main reason is continuous friction through the choke line, but such control tasks are quite time-consuming. However, such a control can be maintained via Managed Pressure Drilling.

Safe & Secure

With its durability and efficiency, the MPD (Managed Pressure Drilling) never compromises on safety concerns. Based on the level of challenges and the required performance, MDP technology is carefully curated while adhering to safety standards.

Low Environmental Harm

The precise control of the drilling system via MPD is an efficient technology that can reduce the contribution to ecological imbalance.

Stability Beyond the Expectations

MPD is an advanced and efficient technology that contributes to stabilizing the entire control, both inside and outside the wellbore. It is made by preventing the impactful losses and fluid influxes, which can even damage the whole of operational line in a worst-case scenario.

Real-Time Tracking

Why are the MPD systems so efficient and valuable? It is due to its inbuilt feature and the integration of advanced systems that track and monitor the wellbore from deep inside, as well as outside. With this, the operational team can make quick adjustments to prevent any issues.

Build Well-Optimised System

The optimised systems built by incorporating MPD technology are a valuable integration that prevents the risk of blocking and keeps the entire line clean and efficient.

Bottom Line

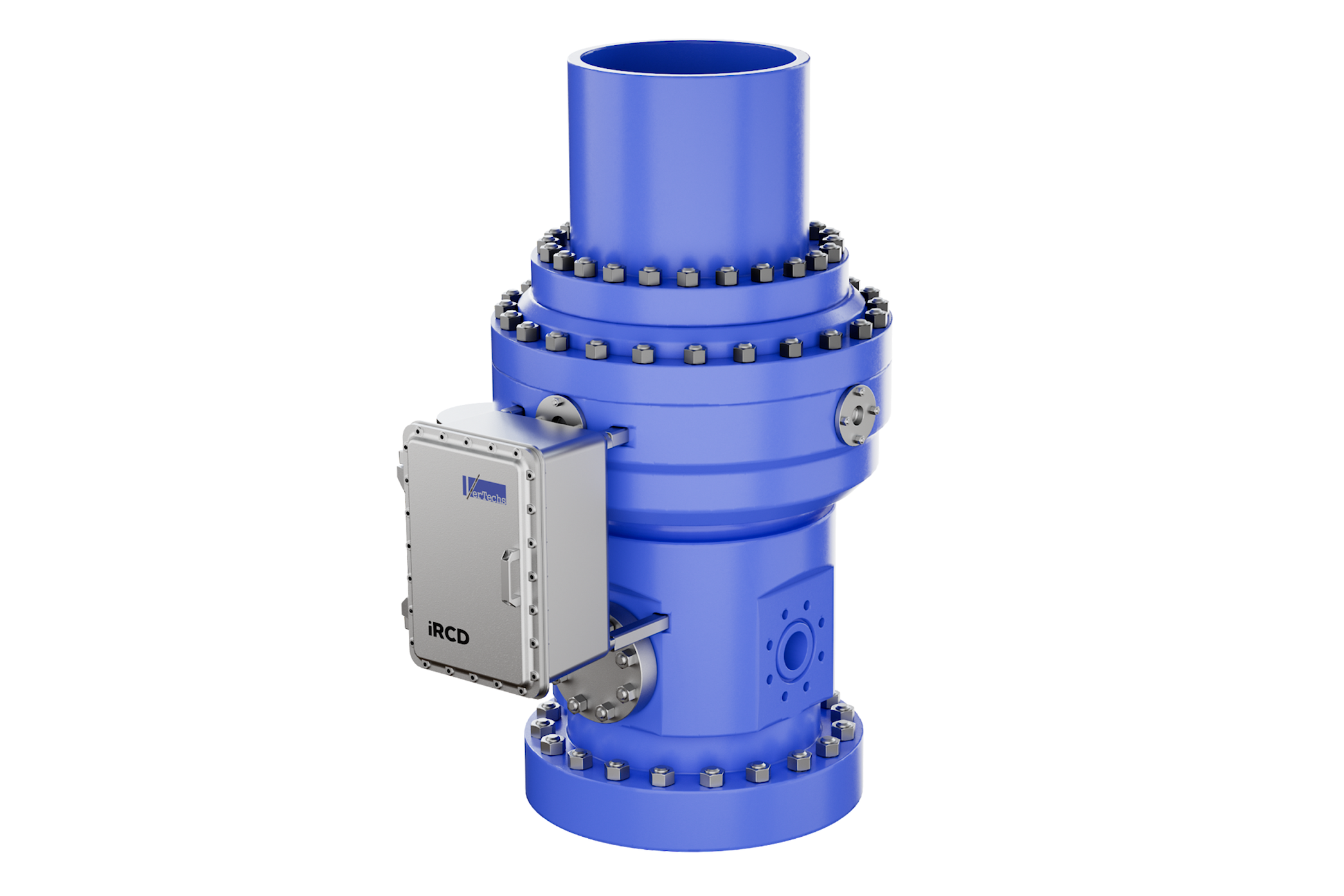

After reading the above, you will become aware of all the benefits that come with Managed Pressure Drilling. However, integrating such technology into a business or operational line is not enough; you need to make the right choice of MPD system, which can’t be made without professional support. However, if this term or the technology known as MPD is new to you, then you may not be aware of how to access reputable professional support. Here is a recommendation for you: Vertchs. We are a leading service provider, and commit to offering solutions and consistent support to individuals seeking to enhance their drilling operational line via MPD (Managed Pressure Drilling).

Let’s make a wise, value-based choice of MPD and ensure a successful integration through a professional. Support at Vertechs. Please contact us at engineering@vertechs.com for further updates or availability information.

Frequently Asked Questions

How can Managed Pressure Drilling solutions at Vertechs improve performance?

MPD is suitable for operational lines operating under high-pressure / temperature conditions or requiring geothermal drilling conditions inside a wellbore, where the extreme conditions need to be maintained at great depths.

What are the four supreme benefits of our MPD solutions at Vertechs?

The highlighted value of our MPD solutions is efficiency, versatility, speed, accuracy, and much more.

What are the applications of MPD systems or solutions at Vertechs?

The primary application of our MPD system is drilling; however, this is not limited to it, and it is constantly expanding its value. MPD is beneficial for cementing, altering the structure, improving production line, conventional tripping, drilling, and more.

What does MPD’s installation team at Vertechs consider to make a successful drilling?

We primarily consider three base factors: hole diameter, hole depth, and hole quality. With this, we allow businesses to maintain an efficient operational line.

Read Our One More Blog(1): How to Control and Prevent Loss Circulation in Oil & Gas Drilling

Read Our One More Blog(2): How Fluid Rheology Impacts Well Control in Drilling Operations