Breaking New Ground: MPD Drilling's Role in Enhancing Oil Recovery

2025-08-07

In today's oil and gas industry, innovation isn't a luxury—it's a necessity. As drilling environments grow increasingly complex, techniques like MPD drilling (Managed Pressure Drilling) are redefining operational standards. At the heart of this evolution is the intelligent use of downhole drilling motors and tools, combined with robust drill bits for oil and gas industry operations, that ensures optimal efficiency and success.

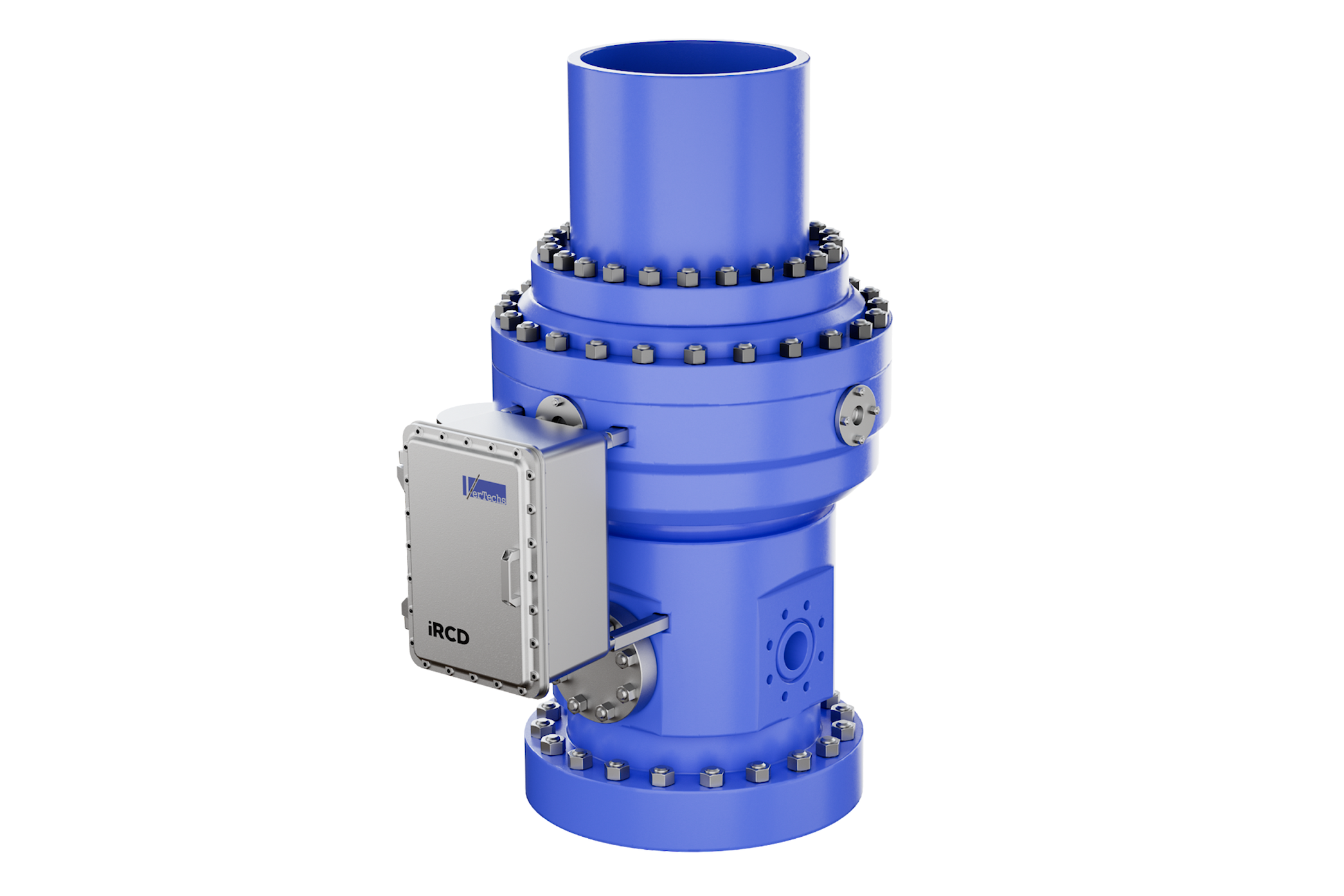

MPD drilling has carved out a critical role in enhancing oil recovery, particularly when traditional methods hit their limits. One of the key components in these high-performance operations is the downhole drilling motor. These motors, specifically engineered to withstand extreme downhole conditions, allow precise directional control, helping operators navigate challenging reservoirs. Companies like Vertechs understand the critical synergy between managed pressure drilling and the right downhole drilling motors, ensuring that every rotation counts towards successful hydrocarbon extraction.

Choosing the right downhole drilling tools isn't just about equipment strength; it's about optimizing the entire drilling system for the unpredictable pressures and formations encountered in deep wells. By integrating downhole motor drilling with sophisticated MPD techniques, operators can fine-tune the annular pressure profile, minimizing risks like kicks and lost circulation. It's a delicate dance between technology and geology, and Vertechs has been leading the way with its commitment to excellence.

At the core of every MPD drilling operation are drill bits designed specifically for the oil and gas industry. Whether navigating through hard rock or abrasive formations, the choice of drill bits oil and gas specialists recommend can make or break a project. High-quality drill bits ensure not only faster penetration rates but also reduce the wear and tear on the downhole drilling motor, thereby extending the life of the entire bottom hole assembly. It’s fascinating how seemingly small decisions, like selecting the correct drill pipe or bit, ripple out into massive operational efficiencies when handled with expertise.

Speaking of drill pipe, it's an unsung hero in MPD drilling operations. The right drill pipe must endure not just the mechanical stresses of rotation and weight but also the pressure fluctuations characteristic of MPD environments. When paired intelligently with advanced drilling and completion software, every foot of pipe becomes a finely tuned instrument contributing to greater control and predictability.

Drill services have also evolved in tandem with the advancements in MPD drilling. Today’s service providers aren’t just offering basic drilling support; they are delivering integrated solutions that marry the physical aspects of drilling with data-driven insights. Real-time data from downhole drilling tools feeds directly into sophisticated drilling and completion software, allowing engineers to adjust parameters on the fly. This results in safer, faster, and more cost-effective drilling campaigns—a win for both operators and investors.

Drilling itself has undergone a radical transformation. What was once a relatively straightforward exercise has become an intricate operation requiring precise orchestration of numerous factors. MPD drilling stands as a testament to this shift, leveraging dynamic technologies to turn potential challenges into opportunities. Companies like Vertechs offer a glimpse into the future of drilling, where intelligent planning, real-time adaptability, and robust equipment like downhole drilling motors and drill bits are seamlessly integrated into a cohesive strategy.

The benefits of integrating MPD drilling techniques into oilfield operations are clear. Operators achieve greater wellbore stability, experience fewer non-productive times, and recover more hydrocarbons than they would with conventional drilling. It’s an ecosystem where everything from the choice of drill bits oil and gas specialists suggest to the calibration of drilling and completion software matters immensely.

One cannot overlook the human expertise that ties all this technology together. Behind every downhole motor drilling success story is a team of engineers and field personnel who understand not just the machinery but also the complex geology they are working within. This blend of technology, experience, and a relentless pursuit of better outcomes is what sets modern MPD drilling operations apart.

As we look ahead, the synergy between MPD drilling and cutting-edge tools like downhole drilling motors, smart drill pipes, and integrated software solutions will only deepen. With firms like Vertechs pushing the boundaries of what’s possible, the oil and gas industry is well-equipped to tackle even the most formidable drilling challenges on the horizon. The future of drilling isn’t just about going deeper; it’s about drilling smarter, safer, and more sustainably.

Vertechs is committed to delivering innovative energy solutions that drive efficiency and sustainability. Our cutting-edge technologies and services are designed to meet the evolving needs of the energy industry. To learn more about how we can support your projects, please contact us, email us at engineering@vertechs.com, or connect with us on LinkedIn.