Harnessing Big Data in Oil and Gas: Vertechs’ Downhole Technologies and Monitoring Solutions

2025-09-30

In today’s evolving energy landscape, the oil and gas industry is increasingly leaning on big data in oil and gas to squeeze out better performance, earlier detection of issues, and smarter decision-making deep underground. Companies like Vertechs are at the forefront of this shift, developing downhole technology and downhole services, especially downhole monitoring systems and tools that feed continuous streams of data from the wellbore into analytics engines aboveground.

Consider a drilling operation offshore, where the wellbore environment is unforgiving: high pressures, high temperatures, turbulent fluids, unpredictable formation behavior. Traditional periodic sampling or manual checks are often too slow or too coarse to catch subtle but critical changes downhole. That’s where downhole monitoring becomes a game changer. A downhole monitoring system embedded in the drilling or completion string can track parameters like temperature, pressure, fluid rheology, flow rates, or geological changes in real time, feeding back into big data pipelines. When downhole technologies such as sensors, smart tools, and telemetry are combined with analytics, the operations team can anticipate problems—loss of circulation, kicks, formation instability—before they escalate.

Vertechs’ product suite illustrates this interplay beautifully. Their REALology Intelligent Drilling Fluids Monitoring System isn’t just a tool for surface or lab measurement; it’s deeply connected to the idea of downhole services and downhole monitoring. It continuously monitors key drilling fluid properties—density, rheology, pH, chlorides, temperature—in real time, automated 24/7, with compliance to industry standards. What makes it potent in the realm of big data in oil and gas is that these measurements are not isolated: they’re streamed, stored, compared, modeled. A downhole model of temperature, pressure, and fluid behavior can be cross-verified against REALology’s data, suggesting exactly how the downhole tool or downhole monitoring system should adjust, or how drilling parameters should be tweaked.

Another Vertechs offering, the REALology HTHP Static Sag Monitoring System, brings the downhole environment into the lab (or field-lab) with high fidelity. It simulates downhole conditions—high temperature, high pressure, variable inclination—and quantitatively assesses how drilling fluids settle or sag. That’s critically important in downhole monitoring and downhole services because fluid sag can compromise well integrity, damage downhole tools, or lead to inefficient completions. By combining real-time monitoring of fluid settlement with predictive modeling based on big data, Vertechs helps well operators stay ahead of the curve.

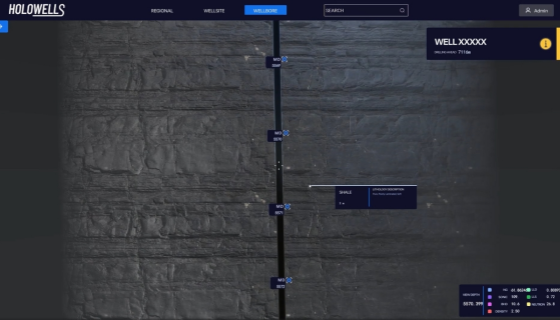

What happens when you connect these tools and data streams across multiple wells, different pressures, formations, fluid types, etc.? That’s where the real power of big data in oil and gas appears: correlations, patterns, anomalies that no single well operator could detect in isolation. Vertechs’ downhole technologies, its downhole tool development, and its downhole services are structured to feed that richness of information. For example, their “BoreSens Real-Time Wellbore Monitoring System” (a downhole monitoring tool) plays into this – sensors placed in the wellbore feed continuous data on wellbore conditions, giving insight into how the downhole environment is behaving as correlated against drilling fluids’ behavior, formation pressure, or mechanical loads.

Downhole monitoring systems are only part of the story; big data also demands software, analytics, and decision support. Vertechs integrates data analytics engines which take the continuous feeds from downhole tools, combine them with fluid monitoring data, downhole service histories, geological models, and more. That allows for early warning of wellbore instability, optimized mud programs, better pressure control, reduced non-productive time, and safer operations. It’s not enough to sense something downhole; operators must be able to interpret signals, flag them, and act rapidly. The downhole monitoring system plus the analytics and responsive downhole services (e.g. adjusting flow, pressure, or fluid properties) form a feedback loop that is central to leveraging big data in oil and gas.

Of course, challenges remain. Putting sensors or tools downhole means dealing with harsh conditions—extreme heat, corrosion, high pressure—and requiring that any downhole technology be robust. Telemetry or data transmission from deep downhole is nontrivial. There are latency concerns; the tools must be compatible with the fluids and mechanical loads in the well. And big data implies not just collection, but management, storage, cleaning, analysis—often in real time or near real-time. But this is exactly where companies like Vertechs distinguish themselves: by combining downhole tool design, fluid monitoring tools, wellbore monitoring, and big data analytics into integrated downhole services.

To bring this to a practical picture: imagine a deepwater well being drilled with an oil-based mud (OBM). The downhole tool senses increasing temperature and pressure near a formation that has a known risk of loss of circulation. Simultaneously, the REALology fluid monitoring system measures that the fluid’s rheology is shifting, chloride content rising, pH drifting. Somewhere else, the BoreSens monitoring sensors are picking up micro flux or small deviations in wellbore pressure. All this feeds into a big data model that Vertechs runs in the cloud or at a base station, which has seen similar patterns before. It alerts the drilling engineer: reduce weight on bit, adjust mud viscosity, maybe initiate a well control protocol. The ideal outcome: you avoid a stuck pipe, prevent a mud loss event, reduce non-productive time, maintain wellbore integrity, and ultimately save cost (and reduce risk).

Big data in oil and gas is more than a buzzword. It’s the fabric through which downhole monitoring systems, downhole technologies, and downhole tools are being woven into daily operations. Vertechs, with its suite of downhole services and monitoring offerings—from REALology fluid systems to wellbore monitoring and strengthening—illustrates how that data fabric works in practice. As real-time measurement, modeling, and responsive action become more embedded, the industry will see greater drilling efficiency, lower risk, and stronger performance. The wells that are safest, most efficient, and most productive will be those whose operators not only deploy advanced downhole technology but use the flood of data coming from downhole monitoring to inform every decision. To learn more about how Vertechs can support your energy technology needs, please contact us or email us at engineering@vertechs.com.

Read Our One More Blog(1): Top Challenges in Maintaining Wellbore Stability Through Fluid Rheology Control

Read Our One More Blog(2): How Intelligent Rotating Control Devices are Changing Well Pressure Management