How big data is bringing revolution in oil and gas well in control

2025-10-10

In the oil and gas industry, well control has always been a high-risk operation where time and data accuracy can mean the difference between safe drilling and frightening failure. As the industry dives deeply into digital changes, large data in oil and gas has emerged as a true game-changer, enabling companies to properly control events, monitor and manage wells. From real-time analytics to future maintenance, the big data in oil and gas Control is redefined and strengthened to make intelligent, fast, and safe decisions to empower engineers.

Understanding well in the modern era

The well control formation refers to the techniques used to maintain balance between pressure and the hydrostatic pressure of drilling fluid. Failure to maintain this balance can lead to dangerous events such as a kick or blowout. Traditionally, operators trusted manual readings, basic sensors, and historical records to manage these pressures - a process that was reactive rather than being active.

With the rise of large data in oil and gas, the well has evolved from prediction to well control reaction. Large-scale data streams from drilling sensors, downhole tools, and surface systems are now collected and analyzed in real time, which gives engineers unprecedented visibility in situations. This digital shift enables more accurate control, better risk mitigation and continuous operational improvement.

Data Revolution: Surface to sub-sub-constituency

Modern drilling operations produce terabytes of daily data. Each rotation of the drill bit, changes in mud density, or downhole pressure add another data point. Through advanced large data platforms and cloud computing, this vast amount of information can now be analyzed efficiently, stored and well -stored and analyzed for decision making.

Here is how big data is well integrated into control systems:

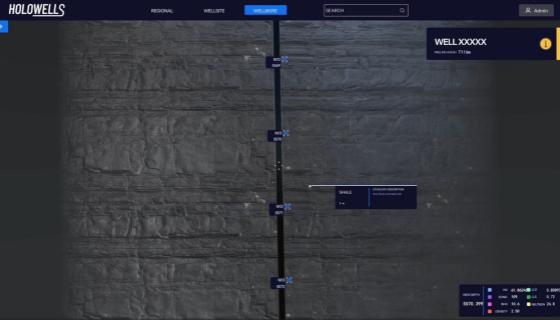

Real-time data acquisition: Smart sensors continuously capture important parameters such as pressure, temperature, and flow rate from Welborner.

Data Integration: Using digital platforms, information from many sources - mud logging units, BOP control systems, and drilling rigs - is integrated into a single, accessible interface.

Advanced Analytics: Machine Learning (ML) and Artificial Intelligence (AI) models process these datasets to identify discrepancies, predict potential kicks and recommend corrective tasks.

The result is an active, data-propelled well control ecosystem that learns from every drilling operation, improves both safety and efficiency over time.

Predictive Analytics: Stop Kick before

In the past, kick detection depended on the surface indicators, such as changes in the volume of the pit or mud flow variation - signs that often appeared too late. Today, large data in oil and gas enables the initial kick through future analytics.

By analyzing millions of data points in real time, the AI algorithm can detect subtle discrepancies in the downhole pressure or gas flow from long before they appear on the surface. Engineers can then take preemptive action - adjusting soil weight, modifying circulation rate, or activating pressure control systems - to prevent an increase.

In addition, historical drilling data refines the future model over time. Each new well contributes to a smart, more adaptive control system that is capable of recognizing unique initial warning signals for various geological structures.

Real-time decision making and cooperation

In a complex drilling environment, decision-making speed is important. Even a few-second delay can turn a managed condition into a full-scale well control emergency.

Large data platforms now enable a real-time view and cooperation between drilling teams. Engineers, geological, and operators can monitor the live dashboard that displays pressure trends, flow discrepancies, and future risk scores. Cloud-based systems ensure that the remote operation centers can provide immediate guidance, helping the rig teams to execute safe and efficient control procedures.

For example, an integrated intelligent pressure control system with big data in oil and gas analytics can automatically adjust the choke valve, maintain optimal soil weight, and ensure continuous pressure balance without manual input. This level of automation not only increases security but also reduces human error - a leading factor in well-control events.

Improve drilling efficiency and cost management

Well control is not only about safety - it is also about economics. Uncontrolled incidents can cause expensive downtime, equipment damage, and environmental hazards. Large data in oil and gas help reduce these risks by improving overall drilling performance.

Through advanced analytics, operators can:

· Pressure control system failures and schedule of maintenance before breakdown.

· Adapt the drilling parameters to reduce non-productive time (NPT) and ensure frequent wellbore stability.

· Improve drilling fluid management and reduce the loss of mud by identifying incompetencies in real time.

By integrating large data well in control systems, the operation is not only safe, but also more cost-effective and durable.

Large data and automation: intelligent well-control future

Well control contains the next frontier oil and in automation automated by large data in gas and AI. These autonomous systems can adjust in real-time without human intervention, using trained forecast models on both historical and live dataset.

For example, intelligent automatic choke systems can dynamically regulate velbor pressure, reacting to immediate changes in formation. Combined with machine learning, these systems continuously improve, learning from each event to increase future performance.

The virtual replicas of well-made well-made the way of testing and training for well control of the well-made well-made data, are also changing. By driving thousands of simulated scenarios, engineers can refine control strategies, predict system behavior, and can safely train personnel in a digital environment.

Challenges in data integration and security

Despite its advantages, applying large data in oil and gas comes with challenges. Many companies still face:

Data silos, where information from various systems remains disconnected.

Inconsistent data quality due to sensor calibration or environmental intervention.

Cyber security risk, as well as the control system, connects more through the cloud network.

To remove these challenges, companies are investing in standardized data architecture, strong cyber security framework, and edge computing solutions, which process data closely, close to the rig site for secure decision making.

Case Example: Clear well control through data integration

Leading Energy Technology firms are already using large data analytics to revolutionize well control. Mixing a pressure sensor, real-time monitoring software, and AI-powered insights, he achieved:

· 50% faster detection of kick,

· Well-related downtime decreases by 30%, and

· Important improvement in environmental safety.

These results suggest that data-manufacturing well control is not the concept of the future is changing drilling operations today.

Conclusions: data-driven safety and efficiency

Large data in oil and gas has entered a new era for well control - an active protection, intelligent automation, and operational excellence defined. The integration of real-time monitoring, future state analysis, and integration of AI-managed decisions ensures that potential hazards are identified and they are reduced long before growing.

As the oil and gas fields continue their digital changes, the adoption of data-centered well control systems will become a standard exercise. In the near future, the autonomous, self-teaching by large data, self-teaching will be redefined to redefine the environment, how drilling comes closer to safety, efficiency, and stability.

In short, big data in oil and gas has not only revolutionized under control - it completely shapes its entire foundation of how to drill, safety, and safely produce energy.

Read Our One More Blog(1): Harnessing Big Data in Oil and Gas: Vertechs’ Downhole Technologies and Monitoring Solutions

Read Our One More Blog(2): Top Challenges in Maintaining Wellbore Stability Through Fluid Rheology Control