How Intelligent Real-Time Circulating Devices Improve Well Control Safety?

2025-12-24

One of the most important parts of drilling operations is safety. One small mistake in controlling pressure or fluid movement can cause serious risks. Kicks, blowouts, and formation damage are some major risks that have happened. That is why well control must be managed. It should be done with great care and constant monitoring.

Technology is changing rapidly. One of the most effective technological innovations is an intelligent, real time circulating device. These devices help in continuous fluid circulation without any stopping operations. This helps drilling teams react faster and reduce pressure variations. This also maintains safe drilling conditions at all times.

In this blog, we will learn how intelligent circulating devices work. Also, how do people play a major role in improving well control safety?

Let’s Understand the Basics of Well Control

The method which is used to manage foundation pressure is called well control. It also prevents unwanted flow of fluids into the wellbore. Safe drilling depends on balancing out the pressure inside the well with the natural pressure of the formation.

Importance

Poor control can lead to kicks, circulation loss, and even pipe sticking. These events can damage the equipment. Also, they can increase costs and put workers at risk.

Support

The control supports real time tools. Traditional well control works on manual measurements. This also led to delayed readings. Intelligent circulating devices not only provide real time data but also continuous fluid movement. This is helpful in reducing human error and allowing faster decisions.

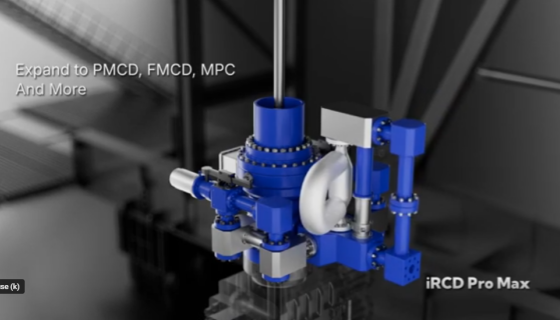

Intelligent Real Time Circulating Devices

The intelligent real time circulating devices are advanced systems. These are installed on drilling rigs. They allow continuous circulation of drilling fluids. This continues even during connections and tripping. Any other operation that needs to stop the pumps also needs these devices.

Features

These are highly effective as they provide real time monitoring of pressure changes.

These provide automated control of flow rates with circulation.

These support safe circulation even in critical operations.

They give an instant response to instability in the well.

These are the features that maintain downhole conditions. These are important for maintaining strong control.

Role of these Devices in the Improvement of Well Control Safety

Continuous Circulation

Continuous circulation is helpful for preventing pressure spikes. During traditional drilling, pumps are stopped to add drill pipe. When the circulation stops, the inside pressure of the well shifts. This sudden change can lead to kicks. The real time circulating devices keep the pumps running smoothly. This helps in preventing sudden pressure fluctuations. This also maintains stable conditions inside the wellbore.

Faster Detection

They help with faster detection of early kick signals. It is the most important step in control. Intelligent devices provide real time data not only on flow rate but also on pressure changes. They also provide data on mud properties and return flow. If formation fluids enter the wellbore, then the device detects the change. This gives the drilling team more time to respond before the situation becomes dangerous.

Better Hole Cleaning

They provide better hole cleaning for safer drilling. Cuttings that remain in the wellbore lead to blockages and pressure imbalance. Real time circulating devices improve hole cleaning. They maintain constant fluid movement. Clean holes reduce the friction that improves drilling efficiency. This also supports well control stability.

Reduced Risk

They are helpful for reducing risk while tripping in and out. Tripping operations normally increase the risk of surge pressures. These rapid pressure changes can cause formation flow or losses. With the intelligent circulating devices, circulation continues evenly. This helps in balancing the pressure and reduces the risk of kicks.

Accurate Data

They are good for accurate real time data for better decision making. Modern drilling needs fast and informed decisions. Intelligent circulating devices offer live pressure readings. They also provide flow analytics with circulation trends. The real time data is helpful for the team to react before major problems. It is also good for reducing dependency on manual checks and subjective decisions.

Supports MPD

MPD operations depend on control of downhole pressure. The devices maintain stable circulation, which directly supports MPD techniques. This improves safety when drilling through high pressure zones. Better MPD performance directly improves control.

Final Call

Strong and stable well control is important for safe drilling. Intelligent real time circulating devices provide a powerful advantage. This is because of maintaining continuous circulation and providing real time data. They help drilling teams respond instantly to risks. As the oilfield is moving towards safer and smarter operations, these devices are playing a key role. These not only protect people but also the equipment and the well itself.

FAQs

Q. How is continuous circulation helpful for control in a well?

A. It keeps the downhole pressure stable and prevents sudden spikes.

Q. Are intelligent circulating devices helpful in reducing equipment strain?

A. Yes, they reduce strain on both pumps and surface systems.

Q. Can these devices support high pressure wells?

A. Yes, they provide real time control. This makes them ideal for an MPD environment.

Q. Are intelligent circulating devices difficult to install?

A. No, many systems integrate easily. They also work with minimal adjustments.

Read Our One More Blog(1): Mastering the Depths: How Fluid Rheology and Advanced Well Tools Are Revolutionizing Wellbore Integrity for the Modern Energy Sector

Read Our One More Blog(2): How Plug and Perf Technologies Are Reshaping Modern Oil and Gas Operations