Mastering Well Control in Land Drilling: Enhancing Safety and Efficiency on Land Oil Rigs

2026-01-02

In the demanding world of land oil drilling, achieving reliable well control is not just desirable — it’s essential. Whether you’re running conventional land drilling rigs in remote deserts, deploying land oil drilling rigs in challenging terrains, or operating advanced land rigs designed for deep wells, the complexity of downhole pressures and the unpredictability of geological formations demand precise control over every aspect of the drilling process. For modern operations, especially those undertaken by a company like Vertechs, well control becomes the linchpin of safe, efficient, and sustainable drilling.

Traditionally, many land oil rigs have relied on mechanical systems to regulate wellbore pressure. But as drilling ventures push into deeper formations or traverse unstable geology, these traditional systems often struggle to respond quickly or precisely enough to sudden pressure fluctuations. That’s why on today’s land oil drilling operations — whether on a dedicated land oil rig or a general-purpose land rig — integrating advanced well control solutions is increasingly seen as best practice.

Vertechs has stepped up to meet these evolving needs with its suite of intelligent pressure control and fluid-monitoring technologies. Their solution goes beyond hardware: it combines real-time data, adaptive algorithms, and automated response to keep wellbore pressure within safe bounds, even in challenging conditions. A core component is the iRCD (intelligent rotating control device), which — unlike conventional hydraulic RCDs — uses an all-electric system to deliver stable, precise control over wellbore pressure during managed pressure drilling (MPD) or underbalanced drilling. Because it forgoes hydraulic cooling and relies on a self-lubricating dynamic seal, the iRCD offers higher reliability and lower maintenance — a critical advantage when deployed on land drilling rigs working in remote or harsh environments.

Another key offering from Vertechs is the IPC-MPD system, which pairs precision electric chokes and intelligent control logic to continuously regulate downhole pressure. This kind of integrated pressure control is especially beneficial on land oil drilling rigs where space is limited and manual intervention is difficult. Compact design, minimal footprint, and automated control make the system ideal for operations ranging from conventional vertical wells to more complex deviated boreholes.

But equipment alone isn’t enough. Effective well control hinges on knowing what is happening inside the wellbore in real time — and that’s where advanced fluid monitoring comes in. Vertechs’ fluid monitoring technologies track critical parameters such as fluid density, viscosity, temperature, and rheology around the clock. By doing so, engineers on the rig can detect early signs of fluid anomaly, losses, or influx before they escalate into serious issues. This kind of continuous, multi-parameter fluid monitoring acts as an early warning system, enabling preventive measures rather than reactive firefighting.

In formations where pressure margins are extremely narrow or the geology is prone to micro-fractures or instability, fluid monitoring alone might not suffice. That’s why Vertechs also offers wellbore strengthening solutions. Their real-time wellbore strengthening system (RWSS) helps stabilize the wellbore by sealing microfractures and preventing unwanted fluid invasion, supporting better wellbore integrity and reducing risks such as collapse or fluid loss. This becomes especially valuable when drilling with land rigs through challenging geologies, ensuring that the wellbore remains stable even under dynamic pressure conditions.

When you combine intelligent pressure control, real-time fluid monitoring, and wellbore strengthening — all optimized for land drilling, land oil drilling, or land oil rigs — you get a holistic approach to well control. Rather than treating each element (pressure, fluid, formation) in isolation, these technologies work together to provide a unified, responsive system. On a busy drilling campaign using land oil drilling rigs, this integrated approach can significantly reduce non-productive time (NPT), minimize safety hazards such as kicks or blowouts, and ensure more predictable, efficient operations.

Moreover, adopting such advanced well control measures doesn’t just make sense technically — it makes sense economically and environmentally. By stabilizing the wellbore and controlling pressure precisely, operators can drill deeper or through more complex formations with greater confidence, reducing the number of wells needed to explore or produce hydrocarbons. That means fewer rigs, less surface disturbance, and a smaller footprint overall. Meanwhile, preventing uncontrolled fluid losses or kick events mitigates the risk of spills or unintended environmental impact.

In the fast-evolving landscape of onshore oil and gas, where land drilling rigs range from traditional diesel-powered rigs to automated, modular systems capable of pad drilling or rapid rig-up/rig-down, the pressure control and fluid-monitoring capabilities of a provider like Vertechs become a true differentiator. Whether you’re deploying a conventional land rig in a remote basin, or executing a high-precision land oil drilling campaign in a geologically complex area, establishing robust well control is foundational to both safety and success.

Well control, after all, is not a one-time setup — it’s the continuous, dynamic process of balancing downhole pressures, fluid behavior, and formation response. And when that balance is managed by intelligent, adaptive systems that monitor conditions in real time and respond automatically, the difference is tangible: fewer surprises, fewer shutdowns, and a more predictable path from spud to completion.

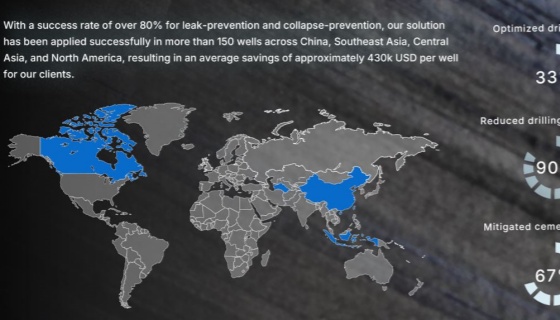

At Vertechs, we are committed to delivering top-tier energy technology solutions that drive innovation and efficiency in the industry. Our comprehensive range of services includes digital application upgrades, artificial intelligence engineering applications, and disruptive downhole technology products, all designed to meet the evolving needs of our clients. With a focus on customer value, we strive to provide cutting-edge technologies and solutions that not only enhance operational performance but also contribute to a sustainable future.

We invite you to explore how our expertise can benefit your operations. Please contact us, via email at engineering@vertechs.com, or connect with us on LinkedIn. Let's work together to achieve excellence in energy technology.

Read Our One More Blog(1): The Revolution of Big Data in Oil and Gas in the Work and Strategy

Read Our One More Blog(2): How Intelligent Real-Time Circulating Devices Improve Well Control Safety?