REALology Intelligent Drilling Fluid Online Monitoring System Facilitates Smart Drilling Rig Upgrades

2025-06-19

Vertechs REALology Intelligent Drilling Fluid Monitoring System recently empowered the successful deployment of China's first intelligent drilling system - the Changlong Intelligent Drilling System.

As China accelerates its push toward digitalization and intelligent oilfield operations, traditional drilling rigs are facing growing challenges: low levels of automation, limited real-time monitoring, and fragmented data analysis. This is especially evident in drilling fluid monitoring - often called the "lifeblood of drilling" - where conventional methods still rely heavily on manual input, subjective interpretation, and are vulnerable to human error. There remains a lack of effective, continuous, and intelligent solutions.

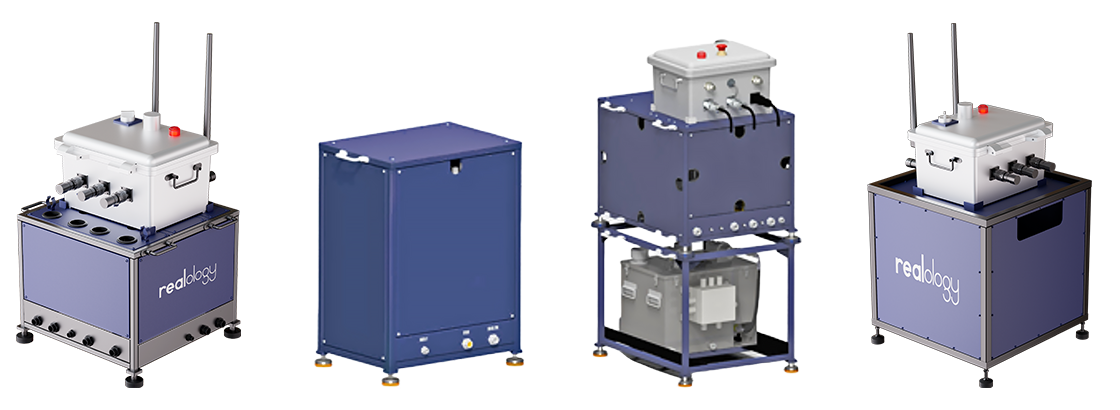

Fig1. Vertechs REALology Intelligent Drilling Fluid Monitoring System on site

Since its official market launch in 2021, the REALology system has been successfully deployed in over 110 wells across Northeast China, Southwest China, the South China Sea, and international locations. Featuring a compact, modular design and full compliance with API RP 13B-1 and 13B-2 standards, it enables flexible configuration to suit diverse rig environments and optimize deployment costs.

Fig 2. Vertechs REALology modules (from left to right: Rheology module, Density module, PH/Chloride Module, Control Module)

| Product Version | Features |

| REALology-Lite | Basic parameter measurement, cost-optimized |

| REALology-Pro | 14 key parameter measurements, compatible with all mud types |

| REALology-Pro Max | Full-performance measurement of drilling fluid, comprehensive data analysis software |

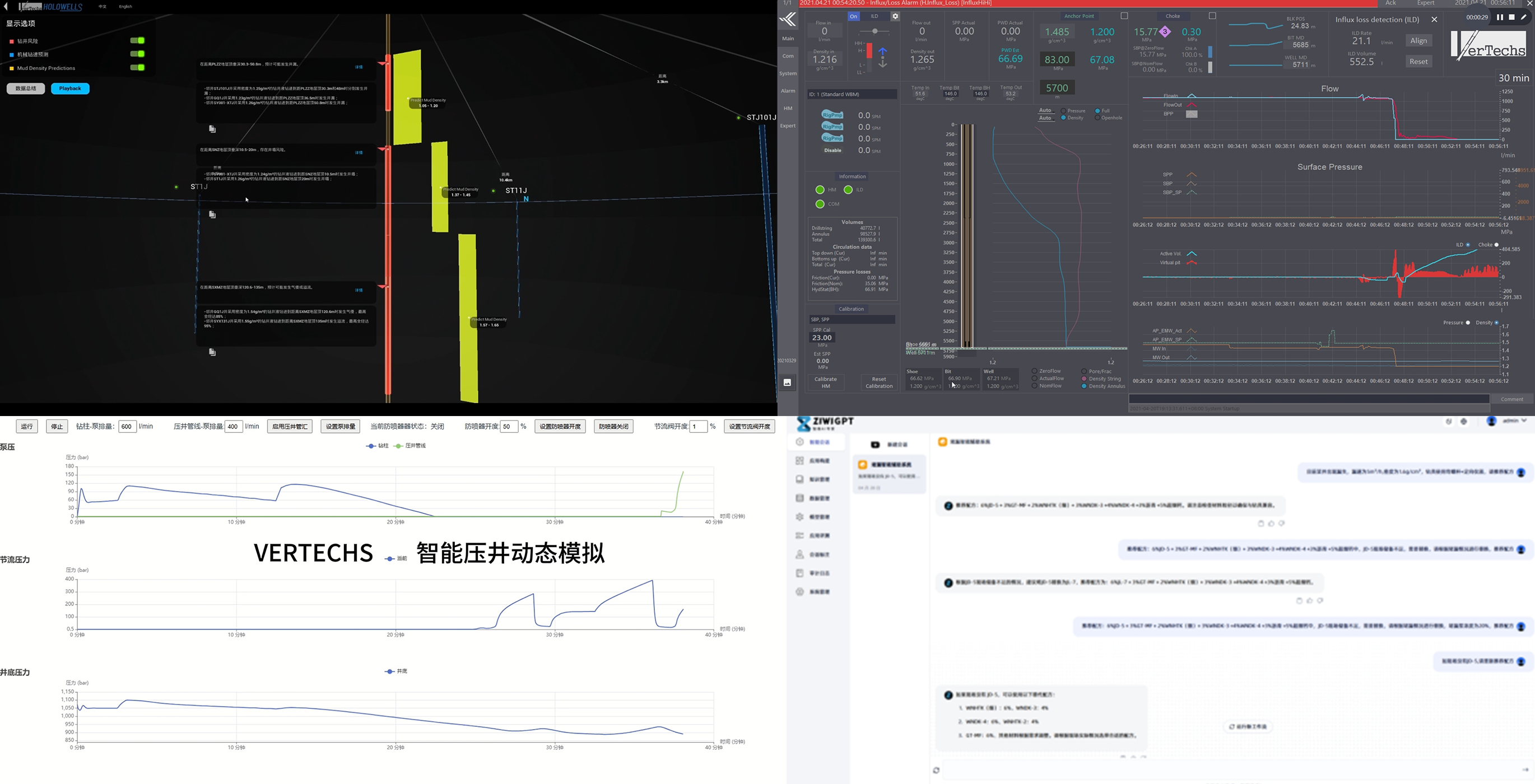

In early 2025, thanks to Vertechs' dedicated digital development team, REALology underwent a significant software upgrade. The latest version integrates a lightweight proprietary AI analysis engine, real-time hydraulic modeling, and intelligent dynamic well control capabilities. By unifying data from drilling fluid properties, operational parameters, and geological inputs, the system delivers real-time risk detection, decision support, parameter optimization, and advanced data visualization - greatly enhancing data-driven wellsite operations.

Fig3. Integrating AI models, RTHM (Real-Time Hydraulic Model), etc.

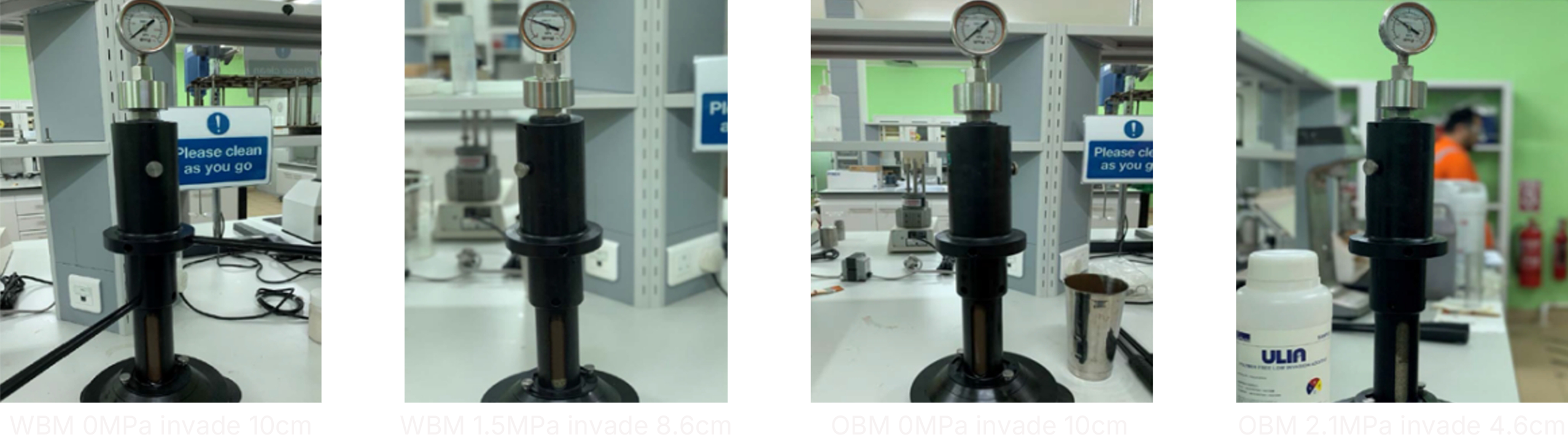

Additionally, REALology can be paired with Vertechs' proprietary HPIT module to perform rapid, on-site qualitative evaluations of plugging materials and sealing performance, improving the efficiency and success of loss circulation control operations.

Fig 4. Vertechs HPIT High-Pressure Invasion Tester

Vertechs continues to partner with industry leaders to advance digital transformation in energy. The successful deployment of the Changlong Intelligent Drilling System marks a major milestone ) demonstrating the power of smart, integrated technologies to reshape the future of drilling.