From Data Streams to Smart Wells — How Vertechs is Unlocking the Power of Big Data in Oil and Gas

2025-12-11

In the shifting landscape of oil and gas, the fusion of big data in oil and gas with advanced downhole technologies is turning wells into dynamic, data-driven systems rather than static holes in the ground. At the center of this transformation is Vertechs Group, a company that has dedicated itself to integrating digital intelligence into every stage of well engineering, well operations, and well monitoring. By combining well engineering know-how with real-time data from well monitoring systems, Vertechs is helping redefine what it means to drill, monitor, and maintain a well.

When you think of traditional well engineering, the image might be of engineers relying on periodic sampling, manual fluid tests, or intermittent observations — snapshots in time that only gradually accumulate into a picture of what’s going on deep underground. But with big data in oil and gas now central to modern drilling philosophy, those snapshots are being replaced by continuous video-like streams of data, flowing from sensors, monitoring tools, and intelligent downhole systems.

Take the company’s REALology Intelligent Drilling Fluids Monitoring System — this is not a lab bench or a periodic sample station. REALology is designed for real-time, automated fluid monitoring throughout well operations. It continuously tracks key parameters like density, rheology, temperature, pH, chlorides — even for water-based, oil-based, or synthetic-based drilling fluids. That data doesn’t just sit in isolation; it feeds directly into analytics platforms that allow engineers to respond immediately when something deviates from expected norms.

Why does that matter? Because drilling and well operations don’t happen in a controlled lab — they happen under high pressure, fluctuating temperature, shifting geological stresses, and unpredictable formation behavior. Without real-time feedback, operators may not notice a subtle change in fluid behavior, or an early sign of wellbore instability, until it’s too late. But with a well monitoring system wired into a broader data infrastructure, changes show up as anomalies in a data stream, alerts get triggered, and corrective action becomes possible before a minor irregularity turns into a major incident.

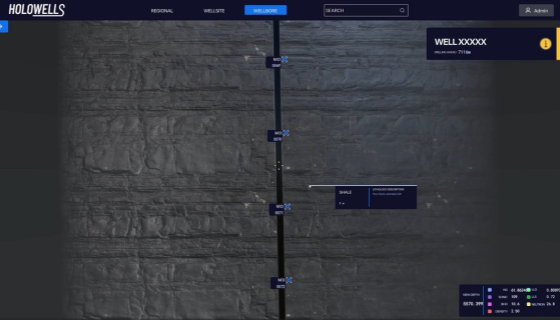

Vertechs also brings more to the table than fluid sensing. Their downhole tools — including real-time wellbore monitoring systems like BoreSens Real-Time Wellbore Monitoring System — gather data from deep underground: pressure, temperature, mechanical loads, cuttings behavior, and more. When combined with the fluid-monitoring data from REALology, and historical performance data from previous wells, the result is a rich big-data enviroment where patterns, correlations, and early–warning signals can be discovered. That transforms well monitoring from reactive maintenance to predictive, data-driven decision making.

In practice, this could look like this: during a complex deep-water drilling operation, sensors pick up a subtle uptick in downhole pressure, while fluid monitoring shows a drop in mud rheology and a shift in density. An analytics engine — fed by big data — identifies that pattern as a precursor to potential wellbore instability or influx. Before the situation escalates, operators adjust mud properties, change drilling parameters, or take well-control action. Because the monitoring system is continuous and integrated, intervention happens in time, well integrity is preserved, non-productive time is minimized, and safety is enhanced.

This synergy between well monitoring systems, well engineering, well operations and Big Data in Oil and Gas is not purely technical — it’s cultural and organizational. It demands bridging the gap between traditional petroleum engineering, data analytics, and digital operations. It requires teams comfortable with sensors, data pipelines, machine learning models, and real-time operations. Vertechs’ global presence — from their Asia-Pacific headquarters to their Middle East and North American offices — reflects the global shift toward “smartdigital” wells, where data flows seamlessly from reservoir to control room, and real-time insight drives decisions.

But it’s not just about drilling. Once a well moves into production, the same principles apply: continuous monitoring, real-time analytics, predictive maintenance. Smart wells — built on the foundation of rich data from well monitoring systems and downhole tools — offer the ability to dynamically manage production, detect early signs of sand-ing, channeling, or abnormal inflow, and adjust operations accordingly. That means safer, more efficient wells, longer production life, and better return on investment.

Ultimately, big data in oil and gas is not a passing trend or a marketing buzzword. It’s the new lifeblood of modern well energy operations — the thread that stitches together well engineering, well monitoring, well operations, and smart decision-making. Through integrated systems like REALology, downhole monitoring tools, and digital analytics platforms, Vertechs is not just selling hardware — they’re enabling a paradigm shift: wells that don’t just sit underground, but think, respond, and evolve based on data. To learn more about how Vertechs can support your energy technology needs, please contact us, via email at engineering@vertechs.com.

Read Our One More Blog(1): How Real-Time Wellbore Strengthening (RWSS) Technology Helps Prevent Loss Circulation in Drilling

Read Our One More Blog(2): Weaving Real-Time Insight: How Big Data in Oil and Gas Meets Logging While Drilling