Weaving Real-Time Insight: How Big Data in Oil and Gas Meets Logging While Drilling

2025-12-05

In the shifting landscape of oil and gas exploration and production, a quiet revolution is underway. It no longer suffices to rely on old-school wireline logging after drilling — the industry increasingly embraces real-time intelligence, marrying the power of big data in oil and gas with the immediacy and nuance of logging while drilling. This evolution is reshaping how wells are drilled, monitored, and ultimately how production decisions are made, yielding efficiency gains, cost savings, and greater operational safety.

The spark of this change comes from growing demand for instantaneous formation evaluation, wellbore insight, and adaptive drilling workflows — and that’s precisely where logging while drilling tools and services shine. The global logging while drilling (LWD) market has been expanding steadily: recent forecasts estimate the LWD market will grow from around USD 2.27 billion in 2024 to as much as USD 4.33 billion by 2032, at a compound annual growth rate of 8.31%. This reflects a clear industry shift: drilling operators no longer wait to finish drilling to gather geological data — they want that data as the drill bit penetrates rock layers, in real time, for smarter, faster decisions.

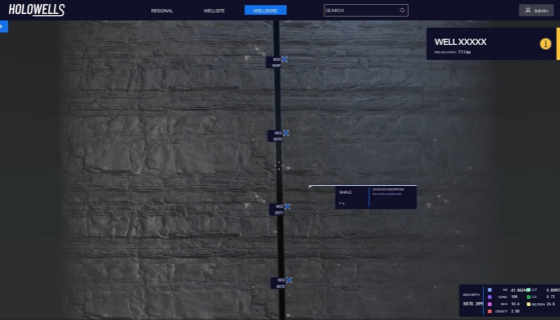

But beyond the market numbers lies a deeper synergy: big data in oil and gas doesn’t just mean more data — it means better-integrated data. Consider how advanced downhole technologies, fluid monitoring systems, and wellbore sensors now work together — continuous data streams from drilling fluid rheology, formation pressure and temperature, geological resistivity and porosity, even stability metrics — all feeding analytics platforms that help engineers see the unseen. Companies that work at this intersection, offering real-time downhole monitoring, fluid analysis, and data integration, are leading the charge. One such example shows how sensors deep in the wellbore, combined with active fluid monitoring systems, can catch subtle changes — maybe a slow shift in fluid density, a rise in chloride concentration, or a gravity-driven sag in drilling mud — long before they become a problem.

With logging while drilling tools relaying formation resistivity, porosity, lithology, fluid saturation, and directional data, operators can steer the wellbore trajectory on the fly, optimize placement in complex reservoirs, and even avoid hazards like unexpected pressure zones or formation instability. That attribute alone helps explain why the LWD market sees robust growth, especially as horizontal drilling, deepwater wells and unconventional resource plays proliferate.

What makes this marriage with big data truly powerful is scale. When data from dozens—or hundreds—of wells, using consistent logging while drilling tools, becomes available in a central analytics platform, patterns emerge. Statistical correlations between fluid behavior and formation type, predictive models for mud sag or loss of circulation, early-warning flags for kicks or borehole instability — these are insights unreachable by traditional periodic sampling or post-drilling logs. In effect, big data transforms LWD from a raw data source into a strategic asset: a constantly learning, improving, and increasingly predictive system.

Of course, this sophistication isn’t trivial. Deploying downhole tools and sensors means surviving extreme temperatures, pressures, corrosive fluids, and mechanical stress. Telemetry and data transmission from deep underground is never easy. And beyond hardware, the challenge lies in managing, cleaning, and interpreting the continuous data flow: the data pipelines, storage, analytics, and decision-support frameworks must be robust. Yet, when downhole technologies, fluid-monitoring systems, and analytics engines converge, the payoff is concrete: safer wells, fewer non-productive hours (NPT), optimized drilling fluid programs, and smarter geosteering.

In this context, the buzzword “Big Data in Oil and Gas” begins to make sense — it’s not digital fluff, it’s the data fabric weaving together real-time drilling insight, geological understanding, and operational control. Logging while drilling becomes the thread that feeds this fabric, providing the raw, high-resolution geological and drilling data needed to drive models, predictions, and ultimately intelligent decisions.

As more operators embrace this integrated approach, we can expect the LWD market to keep climbing. Software and analytics (not just the hardware) are becoming increasingly important: by 2024 software accounted for a significant share of overall big-data-in-oil-and-gas spending, as streaming analytics, edge processing, and cloud integration surged. The industry is learning that having tons of data isn’t enough — what matters is turning those logging while drilling signals into actionable intelligence.

Vertechs is committed to delivering innovative energy solutions that drive efficiency and sustainability. Our cutting-edge technologies and services are designed to meet the evolving needs of the energy industry. To learn more about how we can support your projects, please contact us, email us at engineering@vertechs.com, or connect with us on LinkedIn.

Read Our One More Blog(1): Comparing Traditional And Real-Time Approaches For Managing Loss Circulation In Drilling Operations

Read Our One More Blog(2): How Big Data in Oil and Gas is Fueling the Smart Drilling Revolution